The warm floor in the bathhouse is the most useful component of the whole complex, which forms microclimatic conditions that are comfortable for each visitor, which allows you to easily take general hygiene and healing procedures. The article will discuss how a warm floor in saunas happens, what are its features and installation methods.

Varieties and methods of laying a warm floor system

According to the standard classification, underfloor heating systems are divided into the following types:

- Closed heating circuit from pipelines with circulating coolant. Most often, water is used as a heat carrier, but it is periodically replaced by antifreeze, its aqueous solution, ethylene glycol, etc. Such a replacement of water is necessary so that the system retains its best characteristics in the warm season when it is not used.

- Electric heating - This is a system based on a heating element made of an energy cable or infrared film.

Each of these types has its own distinctive features, advantages and disadvantages. The water system must be connected to the heating boiler, and plastic or copper pipes, a circulation pump that provides for the forced movement of the coolant along the heating circuit, and reinforcing mass are purchased as mandatory components of the system.

The cost of the system is high, but during operation, the owner's costs will be significantly lower than that of electric heating. Cable and infrared heating is cheaper, but it requires electrical energy that rises in price every day.

To arrange a water heated floor in the bath, you must have certain building skills, experience in calculating materials and designing such a system. When using water heating, the owner has additional difficulties in the form of the complexity of the repair work. Usually it comes down to dismantling the existing flooring and replacing the damaged area, or the entire system.

Anyone who decides to install an electric underfloor heating in a bath will ease the task of installing a heating system, but the repair procedure will remain just as difficult. Infrared film - easy to install and repair. To be more precise, when a certain element fails, the rest of the system continues to function without interruption. In the case of film heating, the “cake” of overlap will be the thinnest.

Arrangement of underfloor heating in the bath

In the process of how to properly make a warm floor in the bath, it is necessary to take into account the general and various points in the installation of each type. Almost every variety is mounted on top of a layer of heat-insulating material, after which the floors are leveled by cement-sand or dry screed, on which a facing layer of the final floor covering is applied.

Professionals also recommend laying a layer of waterproofing material, since it will protect the floors from moisture condensation in them when the heating system works. As a waterproofing material, you can use thick polyethylene, and for insulation, mineral wool, expanded polystyrene, expanded clay backfill, etc. are suitable. Ultramodern materials like Penofol with a reflective layer of foil and a self-adhesive base are especially appreciated.

Electrical system with power cable

Externally, with a visual inspection and in the photo, the power cable is almost indistinguishable from telecommunication wiring. Naturally, it differs in functional purpose. The main objective of such a heating element is the conversion of electrical energy into thermal energy with its subsequent uniform distribution within the heated room. The most important parameter of the system is the specific release of thermal energy, which is measured in watts per meter.

Different versions of electric floors can generate from 150 to 400 watts of energy per square meter of heated floor. In the case of bath rooms, it is not recommended to use floors more powerful than 250 watts. It is important to correctly perceive the information about the system provided by the manufacturer, as some report the power of 1 meter of cable, and not the average power of the entire laid heating element in relation to the unit area.

If you produce heating in the bathhouse through a well-equipped electrical system, then its power and the rate of generation of thermal energy can be changed using a thermostat. Manual or automatic control of the system can be carried out by means of temperature sensors.

It is worth paying attention to the fact that power cables come in two types: single and two-core. A single-core cable has an indicator of electromagnetic radiation five times higher than the value for a two-core type. But do not worry about this, because the maximum values for both types do not exceed the maximum permissible standards.

In turn, if we talk about how to properly make a warm floor in a bath, then the use of a two-core cable is a priority, because it is much easier to install. The reason for this is that only one end of the cable must be connected to the thermostat.

When laying an electric heated floor over wooden floors, care must be taken to increase fire safety. For this, wood materials are processed using flame retardants. Such measures are necessary even taking into account the fact that there is no direct contact between the cable and the wood. It is important to check the insulation layer of the heating system itself, as well as to isolate any joints and joints. Before starting work, you must make sure that the resistance of the conductive conductors is at the right level.

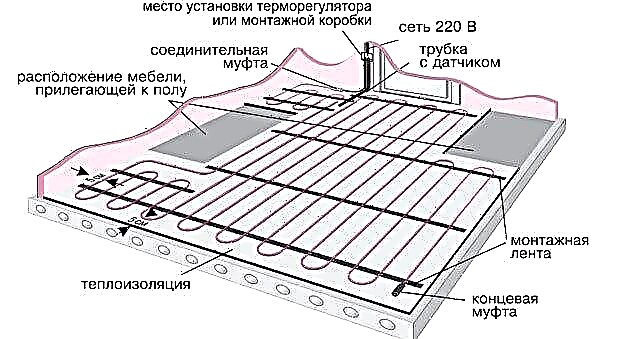

Any professional will confirm that an electric floor heating in a wooden bath must be laid using a mounting grid and special guides with mounts. The guides are used as fixing strips, which will allow you to place the cable lines at an equal distance from each other, taking into account recommendations from the manufacturer and the data presented by various regulatory documents.

These are the following rules:

- from the wall to the first lines of the cable, a 5-centimeter indent must be observed,

- the distance between the turns of the cable is specified in the technical passport of the product, and it is strictly forbidden to reduce this value,

- any heating appliances must be indented 10 centimeters.

The cable to be laid should be distributed evenly over the entire area of the room without significant bending and tension, since in such areas the risk of overheating and short circuit during operation increases.

In no case during the installation process can not depart from the established rules. It is necessary to follow all the recommendations of the manufacturer, specialists and regulatory documents. After the installation of the electrical heating has been completed and the system tested, you can proceed with the installation of the reinforcing mesh and pouring the screed.

In the case of using cement-sand mortar, the system can only be operated after the screed has completely dried, which occurs in no less than 1 month. Upon completion of drying, it is possible to carry out additional testing of the system and only after confirming the successful result, start laying the finish facing coating.

Laying infrared film

If we are talking about how to lay a warm floor in a wooden bathhouse or other building, then the cheapest and easiest option would be to use an infrared film system. The rolled thermal film is easily spread out, and the heating elements on it are fixed with adhesive tape or other cheap materials that are used in the installation of such structures according to the standard. On top of it, you do not need to fill the screed, wait a long time and be afraid that a poorly dried solution will cause malfunctions.

Adhesive mixture is poured on top of infrared mats, the joints of which are tight, if a film-type electric heated floor is laid in a bathhouse under a ceramic or porcelain tile. In some cases, the cladding is laid directly on top of the mats, but experts recommend using an insulating and leveling layer of material.

The infrared heated floor in the bathhouse for tiles or other materials is leakproof and absolute electrical safety. Given their low power in comparison with systems in which the heating element is represented by an energy cable, they can also be used for wooden floors without any concern for the level of fire safety.

The maximum temperature regime of such a system does not exceed 45 degrees Celsius. This temperature allows visitors to the bathhouse to feel comfortable, and also protects the floor materials from deformation. Floors with such a heating system do not increase in height by more than 2 centimeters.

If a thin layer of screed is poured under the finish coat, then all work in the aggregate will take no more than 5 days.

Arrangement of a water floor heating system

If we are talking about how to make a warm water floor in a bath, then the fundamental criteria for the installation method are the technical characteristics of the base on which the installation is carried out, as well as the wishes of the owner.

There are two main laying methods:

- concrete type, implying filling the screed over the laid heating circuit. In fact, the installation technology is similar to that used in the arrangement of the electric heating system. The difference lies in the greater thickness of the screed due to the significant diameter of the pipes used,

- lay type involves laying the heating circuit over polystyrene foam boards or wood flooring. It is used in cases where the foundation or wooden base does not have sufficient strength to withstand a massive cement-sand screed.

The most common is the option with pouring the screed, but it has one significant drawback, which consists in overly long hardening of the solution. As for water heating, its distinctive feature is its absolute resistance to overheating.

This allows you to lay the lines of the heating circuit with almost any interval between the lines. However, it should be understood that with too small gaps between the lines, the total length of the contour will increase, which will lead to a decrease in its efficiency. The optimal value is a step of 40 centimeters.

As in the case of the power cable, sharp bends and creases of the circuit cannot be allowed. The circuit is fixed with clamps and dowels. You can also use a reinforced mesh, to which the pipes are easily wrapped with wire. A more massive reinforced mesh must be laid under the heating circuit than in the case of the power cable.

In the modern construction market, you can find polystyrene plates with pre-assembled fixers, on which it remains only to lay the elements of the heating system. In this case, the fastening method is simultaneously combined with the thermal insulation of the floors.

The heating circuit of the water system and all other branches are connected to a single collector cabinet. Also, various elements of the heating system are mounted in the cabinet: shutter valves, mechanical and automatic regulators.

The most important stage of laying water floor heating is its crimping. Then you can fill the screed or lay the selected materials for this. Naturally, troubleshooting a system is easier if a flat topcoat is used. In concrete, the leak cannot be quickly eliminated, and it will be difficult to detect.

conclusions

From the foregoing, a number of conclusions can be drawn. It is worth noting the fact that there are no special rules regarding the use of a heating system in a bathhouse.

The emphasis can be made on a number of features of the process of arranging floor heating:

- infrared film systems with the simplest installation and operation scheme are leading in this matter,

- the electric floor differs from infrared in the complexity of installation and increased power, in contrast to which the high cost of the consumed electric energy becomes,

- water floors are intended for the most economical owners, but they must understand in advance that the installation will significantly reduce the height of the room, and also have to solve the problem of connecting the system to an autonomous heating system or centralized system. Aesthetically, this system is also the most ugly, because on the photo and during a visual inspection, the intricacies of pipelines and other elements necessary for the functioning of water heating of floors are visible.

Of course, it is possible to combine different types of floor heating, which will create a unified heating system. The installation method and scheme is the personal choice of the owner, which he can make based on the information presented in the article, or by contacting specialists. The latter can help in laying, taking responsibility for all stages - from the purchase of the necessary materials to the commissioning of the system.

Features of the device of heated floors

Depending on the operating conditions, technical features of the bathhouse, foundation structure, options for installing a warm floor system are used.

The water floor acts on the principle of a closed circuit of the pipeline. A liquid-type coolant circulates in a complex manner, which is driven by a special pump. Ordinary water or antifreeze, ethylene glycol can act as a coolant. The system demonstrates a high level of heat supply, creates comfortable conditions in the bath.

The electric type system is created using infrared mats made of film and cable floors. Each of the options has a number of features during commissioning and installation, which must be taken into account by the masters during installation.

The water system requires additional installation and continuous operation of the pump, the use of pipes made of plastic or copper, reinforcement elements. Despite the costs of installation, a water floor heating pays off in just a few years, which distinguishes it from an electrical counterpart. Carrying out installation using infrared or cable heating is cheaper, but affects the energy consumption.

The likelihood of leakage during installation of the water system should be taken into account. Finding a source and repairing the damage is problematic and will require additional costs.

A repair with a cable looks similar. A practical and reliable option is the infrared floor. Damage to one area will not affect the operation of the equipment. The film type does not need a wide screed, which is practical in operation. Installation of underfloor heating for the bath is carried out on special heat-insulating materials based on cement-sand mixture, dry screed. The front side of the coating is laid on the upper part. In some cases, additional waterproofing is used. A thick film of polyethylene, mineral wool, expanded clay or penofol is used.

Electric cable system

Electric underfloor heating in the bath affects the energy consumption, however, it has several advantages during installation and operation. The equipment is based on a convection-type cable floor. The calculation is made on the prepared mesh base. Sale of the floor is carried out in rolls, and installation requires exact observance of safety regulations and grounding standards.

Perform such work better for professional craftsmen. The main advantages of this complex include automatic adjustment of the appropriate temperature, the use of different types of flooring.

Warm floors in the bath with the use of cable are widespread due to high reliability, practicality in everyday use.

One of the disadvantages of this equipment is the dependence on a direct current source, the cost of electrical energy. Floors of this type are used in private baths and commercial establishments.

Cable heating does not require special maintenance during operation. Difficulties arise during the repair work. This is due to problems finding a damaged contact and further replacing the site. This feature is offset by reliability and practicality in everyday use.

What is the difficulty of warming the floor in the bath

Very often the bathhouse is a detached house in the country. It is rare for anyone to have positive temperature in it in winter. More often, it is “heated” only for use, and this is the difficulty. For insulation, you need a material that tolerates freezing / thawing and at the same time is not afraid of moisture. After all, if we are talking specifically about the Russian bath, and not about the sauna, then the humidity in the steam room will be close to 90%. In other rooms, perhaps lower, but also far from normal. So, there are two criteria for choosing a heater: it should not be afraid of periodic heating, but also normally tolerate humidity or not absorb moisture at all.

What is characteristic, often a bathhouse and a change house appear on the site first. And only then begins the construction of the house

What is characteristic, often a bathhouse and a change house appear on the site first. And only then begins the construction of the house

Another option is security. Baths are usually heated by wood stoves, and in most cases the buildings themselves are made of wood. The combination of open fire and wood is always dangerous. Therefore, it is advisable to insulate with non-combustible material. But there is nothing of such kind and therefore they try to choose one that has a high ignition temperature, does not smoke during combustion and does not spread combustion.

How and how to insulate the floor in the bath. Choosing the best options

How and how to insulate the floor in the bath. Choosing the best options

There are still requirements for the device of the floor. We drown the bath not every day, even if it is standing in the yard and therefore it is necessary to think over the design so that during the “downtime” the materials are dried. To do this, you need a working and thoughtful ventilation system, a purged / ventilated subfloor. Otherwise, in just a couple of years, everything will have to be redone.

Materials for insulation

In general, the floor in the bath can be insulated with any insulation. There are rooms with different operating modes and the floor device may be different. Let's look at the most common materials that can be used to insulate a bath.

- Foamed glass (foam glass). Not to say that it is widespread, but it is ideal in all respects for any room. Foamed glass does not get wet, is not afraid of moisture, frost, can withstand temperatures up to 100 ° C without problems, emits nothing, does not burn, does not support combustion. It, like ordinary glass, melts at a very high temperature and does not emit anything. It has very good thermal insulation characteristics, a small layer is needed to achieve the desired degree of protection. The material has low vapor permeability and this should be borne in mind when choosing a floor design. There is one drawback - the price. There is foam glass in the form of blocks, granules, but you can also find trim. The most expensive blocks (about $ 350 per cubic meter), the cheapest - trim (about $ 40 per cubic meter). Blocks can be laid between the lag, granules and trim can be used as backfill. This is many times more effective (but also more expensive) replacement of expanded clay.

New technologies bring new materials. For example, foamed glass as a heater is almost perfect Expanded polystyrene (not polystyrene foam). Best of all is extruded polystyrene foam. It can be in the screed, and between the lags to lay. It has excellent thermal insulation properties, does not absorb water (or rather, it absorbs, but in a very small amount). Up to a temperature of 95 ° C it is environmentally friendly, and above it already starts to secrete not the most useful substances. With regard to floor insulation in the bath, it can be put in any room. The floor is not a wall and it simply does not stand a chance to warm above 40 ° C. But polystyrene foam is flammable and vapor tight. That is, good ventilation is needed.

New technologies bring new materials. For example, foamed glass as a heater is almost perfect Expanded polystyrene (not polystyrene foam). Best of all is extruded polystyrene foam. It can be in the screed, and between the lags to lay. It has excellent thermal insulation properties, does not absorb water (or rather, it absorbs, but in a very small amount). Up to a temperature of 95 ° C it is environmentally friendly, and above it already starts to secrete not the most useful substances. With regard to floor insulation in the bath, it can be put in any room. The floor is not a wall and it simply does not stand a chance to warm above 40 ° C. But polystyrene foam is flammable and vapor tight. That is, good ventilation is needed.

How to insulate the floors in the bath and how it depends on how you are going to make them Mineral wool.

How to insulate the floors in the bath and how it depends on how you are going to make them Mineral wool.

- Stone wool can only be used in dry rooms. Here it will work great. Warming the floor in the bath is best done with other material. If you want mineral wool, look at glass wool. Humidity in the bath is still increased. If wet stone wool freezes, it does not restore its properties after freezing, but immediately loses them by 40%. So after two freezes nothing will remain. Only trash that does not affect anything at all.

Glass wool is very prickly, but not afraid of moisture, which is very important in the bath

Glass wool is very prickly, but not afraid of moisture, which is very important in the bath

From an old memory, many still remember such a heater as expanded clay. While there was no alternative, it could still be considered a heater. Now, to replace a layer of mineral wool with a thickness of, for example, 8 cm, it is necessary to pour 40 cm of expanded clay. Yes, it’s cheap, but it’s afraid of water, which makes it completely unattractive.

Floor cake in the bath

There are two types of rooms in the bathhouse. The first - with high humidity and water in large quantities - is a steam room and shower. The second - with conditions that can be called "normal." This is usually a locker room and a relaxation room. Sometimes these are two rooms, sometimes one. It may still be furnace, but more often the stove is heated from the rest room, and its rear part goes into the steam room.

There is no right solution. Everyone chooses his own. About a dozen options

There is no right solution. Everyone chooses his own. About a dozen options

How to make a floor in the "dry rooms" of the bath

In the locker room and relaxation room, they make an ordinary insulated floor. But the "normal" gender can also be different. In the sense that there are several ways to equip it. What usually converges is that they make wooden floors in these rooms. Still, it is more comfortable and faster in the room it becomes warm. In this case, the floor device itself can be different:

- Ground floor with concrete preparation and floor on the logs. This option is good on soils with high humidity, as it allows you to make high-quality waterproofing of the floor. But you need to think about frost heaving - so as not to “crumple” the stove.

Still, the wooden floor is the “warmest” in feeling

Still, the wooden floor is the “warmest” in feeling

If you don’t want to make a wooden floor in the bathhouse, then make a standard concrete floor cake on the ground. But this option is more for baths with permanent heating. It is quickly impossible to warm up a concrete slab. In this case, you can consider electric floor heating. To prevent cold feet, you can lay down the downed stairs on the floor.

In the washing / shower room and in the steam room, water drainage must be provided. These are the so-called “wet” rooms and the floor cake is different for them. And the device is also different.

Torrential floors in the steam room

To begin with, the floor in the steam room is made only of wood. The tile, firstly, has a high heat capacity. While it is warming up, it is time to go home. The second - it can heat up so that the boots do not save. So, the floor in the steam room is wooden, but it can be torrential or not. Torrential, when the final flooring from the boards is intentionally made alkaline. The board is stacked with a gap of 5 mm or so. And under the flooring is a rough floor, with a bias towards the drain, and the drain through the ladder leads to a drain hole or sewer.

In the wash / shower and steam room, you can make a leaking / pouring floor

In the wash / shower and steam room, you can make a leaking / pouring floor

With this floor arrangement, you can pour water in the steam room. Even in the baths, which are not heated in winter, until everything cools down, it dries. However, if there is ventilation and it works well. For greater certainty, you can not nail the flooring, but make wooden ladders, which after the bathhouse should be taken out into the street or in a more ventilated room for drying.

Warming: how to lay materials

But what about the insulation of the floor in the bath with such a device? And it is necessary to insulate the floor under the lower layer. If as in the figure (floor on the logs), then cranial bars are nailed. They can be a support for stacked polystyrene foam or foam glass blocks. The distance between the insulation and the beam is filled with foam.

For bulk types of heaters, pieces of sheet moisture-proof material (OSB or moisture-proof plywood) are placed on cranial bars. Expanded clay, granular foamed glass or its trim are poured into the resulting “troughs”.

The leaking floor in the bath consists of two “layers”. The first bottom is watertight with a built-in ladder / drain for water. The second is wooden lathing flooring

The leaking floor in the bath consists of two “layers”. The first bottom is watertight with a built-in ladder / drain for water. The second is wooden lathing flooring

To lay mineral wool between lags, you can:

- pull the cord or wire or strong synthetic twine with a “snake”,

- knock off the net (albeit plastic),

- to fill thin slats.

Lay mineral wool slabs at a loss. Their width should be slightly larger than the width of the trough - by 2-3 cm. Then the material holds well, and with the "shrinkage" cracks do not form.

Insulation protection against soil moisture

When using mineral wool, expanded clay or foamglass granules, it is necessary to protect the insulation from moisture that is in the soil. It is always there and always is evaporation. At the same time, no matter how hard you try, part of the moist air will get from the premises into the insulation. And this moisture must be removed. Where? Usually in a subfloor in which vents (vents) are made. That is, if the floor was insulated with mineral wool, expanded clay, broken or granular foam glass, we nail the membrane from the bottom of the subfloor.

To maintain the normal state of the insulation, membranes are needed

To maintain the normal state of the insulation, membranes are needed

The membrane must be with one-sided steam conductivity. It should let off steam from the insulation, but not let it go there. There are such membranes. They are nailed with clamping strips. The holes that are formed in this case are additionally sealed. Only paired with moisture protection, floor insulation in the bath will be durable. Otherwise, in a year you will get problems.

When using plates made of foam glass or expanded polystyrene, additional protection against moisture is not needed. Both that and other material do not absorb moisture, practically do not carry out steam.

Non-spill floor in the steam room

Non-spill floor in the steam room - flooring from grooved boards and organized drain. Boards are laid with a bias towards the drain. Floor drain - concrete or metal (rarely) gutter. The slope of the board is small - 1 cm per meter. Do not need anymore.

How are the leaking floors in the bath - in the steam room or shower / wash

How are the leaking floors in the bath - in the steam room or shower / wash

That is, structurally it is an ordinary wooden floor. Except that you have to make stock. It is made either at the wall opposite the shelf, or as in the figure above, in the middle.

The insulation of the floor in a bath of this design is similar to that described above. Except that:

- The thermal insulation material must be protected from moisture, which still seeps through the wooden flooring. But you also need to remove moisture that has already got there. So again, a one-sided membrane is needed. It is placed so that moisture is not allowed in the insulation, but let off vapors. Below, by the way, under the insulation, if the soil is open, and concrete preparation with spread waterproofing has not been done, a membrane is also needed. It is nailed as described above.

How to make a stock in a steam room with a wooden floor

How to make a stock in a steam room with a wooden floor

How to insulate floors in a bath and how: a scheme of floor insulation by logs

How to insulate floors in a bath and how: a scheme of floor insulation by logsIn general, the pie is standard. That is, we do the floor insulation in the bathhouse according to the usual scheme. The whole difference is in the thickness of the insulation and the presence of a drain chute. And the thickness of the insulation in the steam room is taken taking into account the fact that it is necessary to heat it as soon as possible. Therefore, they usually take 50% more layer than for ordinary rooms.

Tiled floor in a wooden bath sink

Tiles can be laid on the screed. In this case, you need to make a traditional concrete floor with concrete preparation. You just need to remember that you need to organize the flow of water. So immediately determine the level of finish, set a gangway (drain), lay pipes. Then you can start making the floor.

The technology, in fact, differs only at the very end - it is necessary to form a bias towards the ladder. And so, everything is similar. The bottom of the pit is rammed, lay crushed stone in layers, ram. Next, you can make a slab with a strength of M150 and a thickness of 3.5-4 cm or spill crushed stone with thin concrete. The second option is more economical. Wait until the concrete gains 50% strength and you can continue. Put waterproofing on the preparation, insulation on top. How to make floor insulation in the bath in this case? Expanded polystyrene is optimal. It behaves normally in the screed, the layer is not too large, it is not afraid of moisture. In general, he is better not.

How to make a tile floor in the sink

How to make a tile floor in the sink

Expanded polystyrene is laid in two layers. Plates of the second layer overlap the seams of the first. This is for better thermal insulation. Plates of the first layer can be attached to the base with long nails with plastic hats. The sheets are glued together with adhesive tape, you can foam the seams with foam, cut off the excess and lay out the second layer. You can just lay it down, you can fix it with something. In principle, in a small washing, he will not go anywhere. Seams of the second layer of expanded polystyrene are glued with adhesive tape. This is necessary so that the solution does not fill in the cracks - it will degrade the thermal insulation.

Do the floor in the shower also need to be warmed

Do the floor in the shower also need to be warmed

Next, we spread a layer of PVC film on polystyrene foam. This, again, is to prevent the solution from flowing. We roll a damper tape around the room’s perimeter, lay out reinforcement or reinforcing mesh, set up beacons (do not forget to form a slight bias towards the ladder) and fill in the screed. When the concrete has hardened enough, you can lay the tiles. But even with insulation, it will feel cold. There are two ways out - to knock down wooden grilles or to make electric heating. Cable mats are ideal for tiling. In a couple of hours with normal thermal insulation they will warm the floor.

Can tiles be laid if the floor is made in lags? Quite. Again, there are options. You can lay plywood on the rough floor (do not forget about the slope). And you can not plywood, but sheet slate. It is even preferable, since their thermal expansion with tiles is closer than with plywood. Then you can lay the tiles on a special tile adhesive. Special is for complex unstable bases. It is expensive, but the cost of preparatory layers is less.

Still, in wet areas there is nothing better than tile

Still, in wet areas there is nothing better than tile

You can still fill the plywood screed, and lay the tile on it. But it makes sense if you are making water floor heating from heating or from a tank for warm water. If electric, then it can also be laid on plywood immediately.

Features

The bathhouse is a very specific room in which high temperatures and high humidity are concentrated. Collection or discharge of water in this room is carried out on the entire surface of the floor. This adds up to certain flooring requirements. It is worth giving preference to natural wood, in some cases the use of tiles is allowed. At the same time, wood is a good heat insulator.

If you decide to install a warm floor in the bath, then you must consider that this process is a multifaceted task. You have several options for translating this idea into reality.

General underfloor heating is the most expensive option. In this situation, over the entire floor area excluding the steam room, it is necessary to lay the heat exchanger circuit in accordance with all safety rules. Mandatory use of insulation. A screed is poured on top of this circuit, which provides for a certain slope for draining the water. Then, ceramic tiles can be laid on this surface.

The advantage of the presented method is that there is no differentiation of the premises during the construction period. All processes are carried out uniformly.

The list of shortcomings is very long.

- Such a floor is expensive.

- Tiled floors with a slope, especially when wet, will be traumatic.

- Strong inertia of the system occurs. To warm the screed, it will take more time than to warm the steam room.

- If you do not use the system regularly, in winter it can be damaged by the cold.

- It is required to select a separate corner in order to place a heating system and control of a warm coating in it.

The information provided suggests that this option is optimal for public and corporate baths, but not for private housing construction.

A differentiated method where it is necessary to create two systems that will function independently of each other. One will be engaged in floor heating in the dressing room, and the second in the washing department. This gender allows you to solve problems of different difficulty levels. For example, infrared heat-insulated floors are the best option for the dressing room, since in this room the humidity is much lower than the washing compartment. When it comes to organizing warm floors in the bathhouse itself, there are certain difficulties:

- expanded clay and wood have the same thermal conductivity, therefore they are a good heat insulator,

- tiled floors need a special approach for arranging a sewer in a bathhouse.

Advantages and disadvantages

The main advantages of the underfloor heating system are:

- heating the room to the required temperature is carried out by exposure to radiation or water, which provides some comfort when using, since in the head area the air will not be as hot as at the feet,

- due to the lack of conversion, dust does not circulate in the room,

- fungus or dampness will not occur in the room,

- humidity will meet the requirements

- easy care

- there is no possibility of getting a burn, since this is an extremely safe system,

- heat transfer can be independently adjusted,

- the possibility of saving space, since the equipment is located below the floor surface,

- can be combined with another heating system,

- statistics show a reduction in energy costs of up to 25%,

- environmental friendly manufacturing materials,

- the service life is long, it depends mainly on the pipes that were used to create the system.

The warm floor in the bath mainly has only positive reviews. As the disadvantages of the design, it is important to highlight the high labor and financial costs.

It is recommended that the installation of the underfloor heating be carried out by qualified specialists, since without the required knowledge it is very easy to make a mistake that will affect the operation of the system in the future.

Floor heating systems for a bath should be divided into two main types:

- Water option. The presented design includes a closed loop, through the pipes of which the thermal carrier will move. To carry out such circulation, special pumps are used. Water most often acts as a typical carrier, however, there are cases when instead of it there is antifreeze, a solution from it, or ethylene glycol in the pipes.

- Electric modelsfunctioning from electricity. Usually in this case factory electric floors or infrared mats are used.

Each of the presented systems has its own specific advantages and disadvantages. For example, a water floor will cost more than an electric system, however, the costs will be compensated in a few years. Electric underfloor heating are cheaper, but they require high energy costs.

As for the self-creation of these floors, then electrical structures are leading in this matter, which are easier to make with your own hands. In a situation with water heating, competent design and accurate preliminary calculations are required. At the same time, the water structure does not allow to find the damaged area during leakage. It will be necessary to dismantle the entire screed, which is especially problematic when it comes to large rooms.

You can mount a warm floor from the stove or use for this purpose, for example, an air electric boiler. For the furnace and electric boiler, it is necessary to take care of high-quality thermal insulation with reliable materials. It is preferable that the structure is standing on screw piles and the floor is made of concrete.

How to choose?

When choosing a warm floor, you should pay attention to the following criteria:

- The specific power of the underfloor heating should exceed 110 watts per square meter.

- The models supplemented with a stabilizer have a definite advantage, since this will protect against power surges.

- If you decide to install an electric floor in the bath, then installation must be carried out on the free area of the room.

- The choice of thermostat depends on your individual needs. It can be programmable, manual, have a separate power switch, and much more.

Mounting

There are various methods for installing underfloor heating in the bath, which are characterized by general installation rules and certain features. You need to know the walkthrough. Almost all underfloor heating systems should be laid on insulating material, and then covered with a screed on which the floor covering is laid.

In addition to thermal insulation, experts advise using waterproofing, which will prevent power surges.

In addition, waterproofing acts as an obstacle to the formation of condensate in a structure consisting of several layers. Mineral wool, expanded clay, thick polyethylene film and much more can act as a similar layer. Consider installing various systems.

Electric underfloor heating using cable

Visually, this cable cannot be distinguished from an ordinary wire. The difference lies solely in functionality. A heated cable is able to convert electrical energy into heat. Such a system is characterized by the presence of a thermostat, thanks to which you can adjust the power and speed of reaching the required temperature.

In addition, manufacturers usually provide temperature sensors, thanks to which you can monitor the operating mode of the cable system.

It should be noted that the electric cable used in warm floors can be single-core or two-core. The first option is characterized by large electromagnetic radiation, however, it is still within normal limits. The second option is characterized by the simplicity of the calculation, since it does not need to bring two ends to the thermostat, since one is enough.

If the cable floor is laid on a wooden surface, then you need to take care of safety. The wood must be flame retardant, despite the fact that there will be no direct contact between the wire and the floor.

Before installation, it is important to carefully check the cable, joints and connections.

For those who want to equip the bath with an electric heated floor, manufacturers provide various devices that will be useful during installation. These devices are special guides, supplemented with fasteners, and the mounting grid. Using the guides, you can place the cable at the optimum distance from each other. It is important that there is a minimum distance of 5 cm from the cable on the wall, and at least 10 cm from other heating devices.

Film underfloor heating

This is the cheapest and fastest installation option. Here the thermofilm is produced in special rolls. You just need to spread the mat on the floor, fasten the strip with adhesive tape or in another other simple way. It does not require a cement screed, which takes a lot of time. In this situation, infrared mats are poured with tile glue, on which tiles are directly laid. In some cases, the coating is laid directly on the mats.

The presented floors are characterized by excellent tightness and safety. A definite plus is that it can be used with wooden floors. Such a floor is heated to a maximum of 45 degrees, which does not violate the structure of the floor covering. It will take you a maximum of 5 days to complete all the required work.

Water floor

It can be installed in various ways. The choice of this or that option is influenced by the preference of the bath owner and the technical characteristics of the floor covering. The most common are two installation methods.

- Concrete type, which is similar to installing an electric floor heating. The only difference is that the pipes are thicker.

- The lay-on method, which is especially popular, as it does not overload the floor covering.

Installing a warm floor using a concrete screed is the most common option, the only drawback is that it needs a fairly large time outlay. In this case, you can not be afraid of overheating, so a similar method of installation is chosen quite often. Note that it is not recommended to install pipes close to each other. The optimal distance between them is 30 cm.

This case does not include bends and kinks. Pipelines must be fastened with clamps and dowels. In some cases, wire is used. The presented method involves holding the pipeline in a spiral or a snake. To build such an option is not very difficult.

It is necessary to start making the structure in the ground. Then fill and lay all the necessary material.

Tips

Installation of a warm floor in the bath provides convenience and comfort in this room. You can achieve maximum effect only if you choose and install the system correctly. It is important that all rules are followed, especially with regard to security. It is extremely difficult to install if you do not have the proper skills and experience in this area. This is especially true of the case when you give preference to a water heated floor, because here you need to properly connect the pump and other products that ensure the correct operation of the system.

When it comes to installing electric underfloor heating, certain care is required here and waterproofing is absolutely necessary. For the effective functioning of such a system and ensuring safety, it is important to pay special attention to studying the instructions of a particular manufacturer, since each floor is characterized by features. In this case, manufacturers usually give certain recommendations for installation.

See how to make a warm floor in a bath in the next video.