Modern apartments in apartment buildings have a diverse layout, but they all have one common problem in common - insufficient sound insulation. This threatens that the sounds, sometimes quite loud, coming from the neighbors, will interfere with a good rest and a quiet life. The issue is solved by installing soundproofing. The main thing for this is to choose high-quality, modern and safe materials that will not only save you from unnecessary noise, but also do no harm to the residents.

Soundproofing Options

Most often, gypsum plaster is used during repair and construction works. It has many positive properties, but sound insulation is not one of them. To get rid of annoying noise, you can apply various methods and use a wide variety of materials that absorb sound. The main thing is to decide on which one is suitable in each particular case. Consider the most popular of them.

Styrofoam

Very often, consumers use conventional polystyrene for noise insulation. It has a low price and does not cause problems during the work. You can buy this material in almost all specialized stores. In addition, it is very light, so transportation, as well as installation, will not be difficult.

Of course, the foam has sound-suppressing properties, but other materials cope with this task much better.

Drywall

A very popular option is in which drywall is used to suppress noise. In addition, with its help it is possible to realize non-standard and unusual design solutions. When using drywall, you must remember about the mandatory use of insulation, which has remarkable acoustic properties. Data on these properties must be indicated on the product label.

The insulation is sold in rolls, before use it must be cut and secured inside the structure. Between the wall and materials it is necessary to leave air, with its help excess moisture will be removed, and noise absorption will be more effective. This method does not require large financial costs and is quite effective.

Glass fiber and mineral wool boards

Plates made of fiberglass and mineral wool perfectly absorb sound, but have their own characteristics when used. First of all, they must be installed in frames, which are subsequently sheathed with drywall, which inevitably leads to a decrease in the size of the room. However, this method is very effective.

The material is environmentally friendly, so it will not harm the health of residents and visitors. But the plates themselves have a fairly high price, because of which the method has not found wide application.

Polyurethane panels

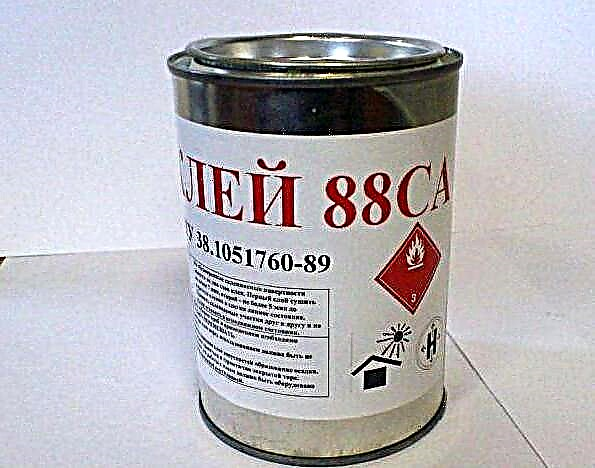

The basis of the material is acoustic foam. The panels have a thickness of up to 10 centimeters and are mounted on the walls with glue.

Installation work can be done independently, as they do not require special skills.

Liquid insulation

It is a special mixture that is laid in a thick layer on top of the plaster. The method is quite effective, but it must be borne in mind that the composition will need to be closed with drywall or decorative plates.

Roll and sheet cork

It carries mostly decorative function. However, the coating is quite thick, and also has a peculiar structure, which gives it sound-absorbing properties.

Keep in mind that the method is not too effective.

High density membranes

The use of this material helps to cope well with the problem of extraneous noise in the room. The membranes are very thin, but this does not negate their excellent sound-absorbing properties. In addition, they are easily attached to the surface and held firmly on it for a long time.

Soundproofing plasters

This option is very popular and is often used for decoration. The price of such plaster is low, and you can perform work on its application yourself. In this case, additional decoration is not needed.

The mixture can be used in any room, as it is environmentally friendly and completely safe.

What to consider when choosing

Sound insulation options are many, so the consumer needs to choose the method that is most suitable in a particular case. First of all, you need to consider the size of the room. It is undesirable to sheathe a small room with thick blocks and panels that will take up extra space.

Stucco ceilings and walls are best combined with materials that can reflect sound. Typically, fibrous, porous and granular panels are used in this case.

If it is possible to turn to specialists to install noise insulation, as well as if there is a sufficient area of the room, it makes sense to install a more complex structure, which includes a sound absorber laid in several layers.

When choosing a soundproofing material for plaster, it is necessary to carefully study all the information about it, and then the result of the work will fully meet the expectations of the consumer.

You can learn about how to make budget soundproofing of walls with your own hands from the next video.

Soundproofing with plaster in public places

In some public institutions, noise protection is becoming the most important task, as they are designed to provide relaxation and comfortable silence for visitors. In restaurantswhere sounds from the street do not reach in theaters and cinemas, where during the screening of films and performances you can’t hear what is happening outside the hall, - everywhere special acoustic noise-proofing plaster is used that reliably absorbs the noise arising from the outside.

Where else is such a plaster applied? With this finishing method, the following are protected from noise: public places:

- restaurants, cafes, catering centers,

- office centers, conference rooms,

- libraries, thematic circles and sections, reading rooms,

- courthouses, counseling centers,

- production facilities located near the residential sector.

Given that even such large rooms are reliably protected from noise with the help of plaster, there is no doubt that in your home you can easily and quickly create a comfortable environment that will not be disturbed by loud sounds.

The insulating properties of such plaster are ensured by special composition of this material. Soundproof plaster consists of lightweight fillers, which are divided into small granules with dimensions of about 5 mm. Usually used for these purposes. crushed pumice, vermiculite or expanded clay. Due to the hollow structure, a small weight and density of such a material is ensured.

Often when creating plaster for sound insulation, aluminum powder is also used. In the process of drying out of such a powder gas comes out, providing greater porosity. Due to the loose and textured internal structure, the sound is weakened and lost in the plaster, starting from small particles. As a result, extraneous noise does not reach the room, since completely muffled inside the plaster.

In order for the soundproofing plaster not to lose its protective properties, it is undesirable to paint such a wall with dense paints, for example, enamel. Due to their density, such paints and lacquers will penetrate the pores and clog them, so the sound cannot be muffled in the porous structure of the plaster. It is also undesirable to glue wallpaper on such plastersince adhesive applied to the surface can also impede isolation from noise.

Original decorative ceiling plaster: read about the types, properties and advantages, as well as details about the technology of applying such plaster.

Read in this article how to paint the ceiling with acrylic paint: detailed instructions for painting the ceiling, tips, videos.

Soundproofing apartment with stucco

It is extremely important to ensure sound insulation in the apartment, because it is here that you will relax, and noisy neighbors can prevent you from relaxing. This is especially true for houses with dense walls, since excessive density contributes to high noise penetration.

Please note that plaster with soundproofing properties not harmful to healthTherefore, this method of protection is suitable even for a child’s room. And thanks to the ability to create an original embossed surface, it is not at all necessary to apply decorative finishing materials to the plaster layer, since even the plaster itself can be decorated in accordance with the style of the room.

Stucco with soundproofing properties is very popular due to its practicality and versatility. And it is highly expected that the superiority in this popularity belongs to Knauf soundproof plaster.

She is not only reliably protects from noise, but also It is environmentally friendly, fairly durable, waterproof, able to let steam through while maintaining the structure of the walls. Such plaster is resistant to high temperatures, and also helps protect walls from damage.

At the same time, sound insulation with plaster is considered inexpensive way to protect against noiseand with proper use and care a positive result can last several decades.

Please note that the features of wall covering with such a material are slightly different from standard processes. In order to apply the plaster to the wall, there is no need to use special beacons, as they can ensure the passage of sound. Desirable do not apply plaster too wide.

If you want to ensure the maximum soundproofing properties of acoustic plaster, you can create between the wall and the protective layer an additional layer of metal mesh with small cells (10x10 mm). Thanks to this layer, you can create air pockets under the plaster, making it even harder for sounds to penetrate the room.

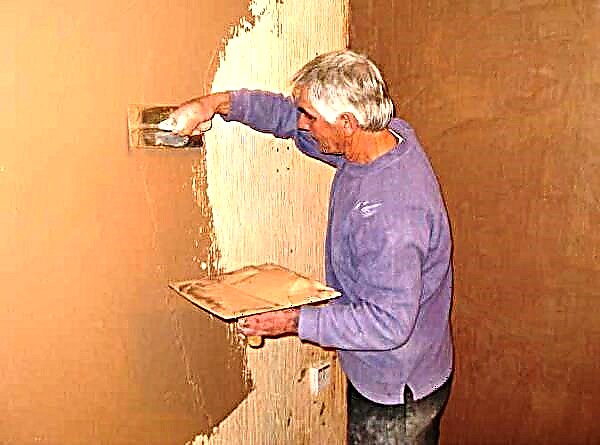

Application of acoustic plaster: the main steps

As in any finishing work, the initial stage in the process of applying plaster to the wall should be surface preparation. The wall is leveled, cleaned of foreign materials, and then primed with a special solution of cement and sand.

After the soil is almost dry, you can start applying plaster. Control so that the layer is even and uniform, and its thickness did not exceed 2-2.5 cm.

If the work is completed before the entire wall is covered with acoustic soundproofing plaster, make the edge one third thinner than the whole layer: it will be easier to continue working, applying a new lap mix. If you leave a uniform layer on the edge of the layer, then with subsequent application of the plaster, seams will appear that will catch the eye.

In addition to paint, for decorating such walls, you can use fabric or wooden grilles.

Although soundproofing plaster is considered a reasonable way to protect against noise, she will not always be able to protect from excessively loud sounds.

If in your house there is a risk of such noise, it is advisable to combine acoustic plaster with other soundproof materials.

See a selection of photos of glass partitions in the apartment - all the secrets and subtleties of technology are described in detail.

Read here about using wall mounted vertical radiators.

With proper surface preparation, compliance with all conditions of application and use of plaster, you can forget about the problem with extraneous noise and create not only a cozy, but also a beautiful atmosphere in the room.

Soundproofing Overview

Options for insulation materials fall into three categories:

- Absorbing. The effect of obstructing sound is performed by converting it to heat by damping the intensity of the reflected waves. These are polyurethane panels, liquid sound insulation of walls, acoustic plaster, carpet, etc.

- Isolating. Sound waves bounce off the surface. This panel Knauf, Fonstar, TechnoNIKOL soundproofing, Soundguard.

- Thin wall insulation. It is carried out using a film or membrane coating produced in rolls. It works by neutralizing sound waves. High demand are the products of firms Texaund, Rockwool.

The classification of materials for sound insulation according to the level of stiffness is presented in the table:

| Power | High | Average | Low |

| The foundation | Mineral wool with porous filler. | The made foam polyurethane, polyfoam. | Cotton wool, fiberglass. |

| Weight | up to 400 kg per 1 m3 | up to 130 kg per 1 m3 | up to 40 kg per 1 m3 |

Before buying, you should consider two factors:

- Sizes. For small rooms it is impractical to use suitable materials, otherwise they will significantly reduce the usable area. In such cases, film or membrane roll insulation is used.

- The purpose of the room. Soundproofing plaster or mineral wool is not used in the kitchen. Due to the high humidity, it will quickly become worthless.

Mineral wool

Mineral wool is widely used for soundproofing rooms. With it, you can effectively delay up to 80-90% of noise. It is made from fibrous filaments made from molten basalt rock.

- low cost

- light weight

- convenience, ease of installation,

- thermal insulation.

- complete loss of properties in contact with moisture,

- possible release of formaldehyde during combustion,

- the need for a frame.

Cork panels

Cork to reduce the ability of walls to transmit sound began to be used relatively recently. It allows you to almost completely get rid of impact noise. Advantages of cork panels:

- environmental friendliness - the cork is absolutely safe for people,

- moisture resistance

- protection against decay, mold, fungi,

- durability - serves more than 40 years.

Disadvantages of cork soundproofing walls:

- installation complexity

- burnout with prolonged exposure to sunlight,

- lack of protection against fire, exposure to high temperatures,

- high price.

Polyurethane boards

Polyurethane allows you to completely protect the room from all types of noise. That is why it is used in arranging recording studios.

- absolute noise protection

- small thickness - not more than 1.5 cm

- a light weight,

- ease of installation.

Only one drawback: very high cost.

What is sound and acoustic insulation of a room

The word “acoustics” from Greek translates as “hear” or “listen”. This is the name of science that studies sound and its nature. The word "isolation" means separation, creating interference with the passage of something. Soundproofing walls in the apartment - creating a barrier to the passage of the sound signal. There are two ways to prevent the spread of noise: reflection and sound absorption. To reflect sound waves, you need a special “mirror” - the surface geometry of the cladding. Decibels of external sound can be reduced due to the structure of the material of the building envelope, as well as its multilayer.

The main sound-absorbing materials having a porous soft structure:

- polyurethane panels (foam sheets are glued, coating thickness up to 10 cm),

- Styrofoam,

- cork (roll and sheet, if the crumb diameter is 3 mm, and the total thickness of the sheets is 8 - 10 mm, it can be a final sound-absorbing coating),

- fiberglass and mineral wool boards (plate thickness> 30 mm, require a frame and are covered with drywall or gypsum boards),

- liquid sound insulation (a thick layer of the mixture applied to the plaster is covered with plasterboard or coated with decorative plates),

- acoustic plaster compositions.

- gypsum plasterboard or gypsum board,

- soundproofing decorative panels (cardboard frame filled with mineral aggregate, for example, quartz sand),

- puff boards of soft fiberboard with polystyrene foam gaskets (thickness 1 - 10 cm),

- soundproofing sandwich panels (ZIPS),

- wood fiber panels,

- soundproofing mixtures,

- high density membranes.

Materials that are coated with plaster after installation are called soundproofing for plaster. Manufacturers of soundproofing plaster compositions offer, as a means of lowering the level of incoming noise, the so-called sound- or sound-absorbing compositions - acoustic plasters (AS).

Stucco Features

From the usual data, stucco compositions differ in sound-absorbing fillers.

- monolithic soundproof coating without joints,

- the coating structure should be dense without various delaminations and cracks (even micro) that are conductors of sound,

- obligatory removal of metal beacons after plastering (homogeneous beacons become conductors of sound),

- the appearance of conventional plasters,

- the possibility of tinting as you wish,

- maintainability

- spraying is environmentally friendly,

- coloring, especially with dense enamels, significantly reduces sound-absorbing properties,

- do not overwrite the top layer (cover with a cloth or panels).

As an example, we give the technical characteristics of perlite compositions:

Ultimate compressive strength (kg / cm2)

Water - 540.

Water - 415.

The effectiveness of a soundproofing plaster composition can be enhanced by applying a layer of it on top of a pumice concrete base or chipboard (on a porous base).

Composition

Most often, the following binders are used for the basis of soundproof plaster mortars:

- gypsum,

- Portland cement,

- Portland cement slag

- lime,

- caustic magnesite (in powder form - magnesia cement).

Mixtures may also use mixtures thereof. In gypsum compositions to slow down the setting add a lime-glue moderator (1% by weight).

Sound-absorbing solutions are distinguished by bulk density in the range of 600 - 1200 kg / cubic meter due to the light porous filler - porous granules:

- pumice (or pumice sand),

- perlite

- expanded clay,

- slag

- foamed glass.

The grain size is up to 3-5 mm, as a rule, one fraction is used in the composition.

The most famous solutions have the following composition of soundproofing plaster:

- acoustic APC: 1: 3-4: 1 (cement, pumice sand, water),

- cement with pumice or vermiculite (granule size up to 3 mm) - 1 part cement, 4 part filler (dry components are mixed and diluted with water, cement plaster base increases adhesion and sound absorption properties, applied with a layer of 25 mm, without overwriting the surface),

- cement with slag 1: 4 (fraction size 3-5 mm, superimposed on a cement plaster base),

- gypsum with sifted slag with a diameter of up to 2 mm (slag is closed with gypsum milk, the solution is applied without grouting to a primed base, water-resistant coating),

- acoustolite - magnesite with pumice with a diameter of 1 - 2 mm (caustic magnesite (4.8 l) with particles up to 0.25 mm is mixed with pumice (19.2 l), hydrochloric acid is introduced into the mixture (strength 12 o, volume 6.4 k), mix until evenly moistened, apply even to an untreated base),

- cement with asbestos chips and sand with a thickness of 5 - 10 mm (1: 2: 2 up to 1: 6: 1, is applied mechanically to the preparatory cement-sand 1: 2 layer 5 - 6 mm).

There are other components in the finished soundproofing commercially available. Manufacturers sometimes add aluminum powder, as a result of which, when the solution dries, pores from the outgoing gas are formed, which increases the sound-absorbing properties.

Advantages and disadvantages

Relative to other acoustic materials, sound-absorbing plaster has the following advantages:

- ease and speed of application,

- seamlessness

- undemanding to the evenness of the base,

- universality (any, even complex forms are created),

- environmental friendliness.

How coating has its advantages:

- vapor permeability allowing the walls to breathe,

- low dead weight (does not put a heavy burden on the foundations),

- maintainability

- additionally has insulation properties,

- fire resistance

- not a topcoat,

- high cost (compared to conventional mineral compounds, but significantly lower than other soundproof materials),

- the coating is not elastic and (like mineral) is afraid of vibrations.

Application area

Sound-proofing plaster is used in rooms requiring high sound-absorbing qualities.

They are most in demand in:

- museums

- theaters

- cinemas, exhibition spaces,

- libraries

- galleries

- educational institutions

- arts and leisure centers

- sports facilities

- conference rooms

- airports, station buildings,

- on some types of production,

- office premises

- medical institutions

- psychological relief rooms,

- luxury housing.

How to apply

Soundproofing solutions do not differ from other types by application methods. The difference is only in the case of applying soundproofing to the walls on the plaster. In this case, the surface of the building structures is prepared specifically for it. Additional measures are also taken to improve the performance of the acoustic coating. For example, a 10 mm cement primer from a 1: 3.5 or 1: 4 mortar with the addition of lime paste up to 10% is pre-applied under soundproofing plaster. Apply the mixture on wet soil. The final layer of the solution is leveled with a trowel, but not overwritten. After drying, tighten with a cloth or grate.

Soundproof plaster is applied in three layers:

- preparation of walls

- priming,

- installation of leveling beacons,

- spray layer of creamy consistency (for the base of wood its thickness

9 mm, for concrete and brick surfaces - 5 mm),

Foundation preparation

Strictly speaking, most soundproofing plasters do not require special leveling of the base. Some, for example, Acustat, Acoutex, etc., applied in a thin layer, require an even base. In this case, the wall before plastering is leveled or mounted on it with gypsum plasterboard (gypsum plasterboards).

In all cases, the surface is cleaned of the old peeling coating, wallpaper. Metal parts are removed or coated with anti-corrosion agents. Neutralize efflorescence, foci of biodefeat. Remove grease stains. On the brick walls, masonry seams are deepened. The base is cleaned of dust. Coat with a primer (2 layers), if necessary.

One of the measures to increase sound absorption is the installation of a metal mesh (10 mm cells), as well as the application of a 10 mm cement mortar with sand.

On curved walls and in the case of applying a thick coating on the base, beacons are installed. The base is well dried. The adjacent surfaces (door frames, window sills, etc.) are sealed with masking tape.

Tools

- one and a half

- narrow spatula

- the rule

- trowel / trowel,

- the rule

- Maclowa

- mixer,

- mixing tank

- stepladder or platform

- rags.

Solution preparation

Dilution of the solution and the application of soundproofing plaster requires an ambient temperature of not lower than + 10 ° C, not higher than +30, humidity - up to 60%. The preparation itself is carried out in stages:

- Pour dry mixture into a container of 30 - 40 l (it is necessary to use the entire volume from the package for kneading).

- Pour cool water in the volume indicated on the package.

- Mix

10 min.

Cement-based mixtures have a life of up to 4 hours.

Plaster compositions are prepared a little differently, since they are suitable for less time.

Finishing work

If noise insulation is mounted under the plaster coating, then start with it:

- Soundproof panels are glued or attached to the wall.

- Then the joints are closed and a sand-cement leveling layer is applied, the thickness of which depends on the curvature of the walls (optimally 10 - 12 mm).

- Soundproof plaster is applied to it in layers.

15 mm Each layer is leveled with a trowel. Layers are applied when the previous one dries. Manufacturers do not recommend making layers thicker, since the potential for cracking increases. The total thickness of the layers

40 mm. If you want to take a break in plastering, and the wall is not plastered to the end, then on the edge of the laid layer make a step 30 mm wide. After resuming work, they step on this step, applying a fresh solution. This avoids the appearance of a seam and the transmission of sound along it.

If a sThe walls are insulated with plasterboard sheets; gypsum mortars are best used as soundproofing plasters. Lighthouses leave.

Myths, misconceptions and rules of use

Soundproof plaster for walls is advertised as a panacea that can get rid of any noise. This is an advertising move. In fact, if all the work is done correctly, using AS can lower the noise level by 8 dB, which is similar to the effect achieved by erecting a thick brick wall. At the same time, the sound comfort in the room becomes a third to a quarter better. If you need to achieve great results, you can not do without the installation of acoustic structures. You can perform a soundproofing layer not only indoors, but also outside the building.

The second myth is related to cork. It is effective only in the case of isolation of impact noise, if it is laid under the floor or under the feet of a neighbor in the apartment from above. It muffles the footsteps, but not the ringing voice or the sound of the TV. That is, in all other cases, the effect of cork coating is only insulating.

The sound-absorbing effect can only be increased by increasing the thickness of the sound-absorbing coating. Therefore, AS is best used in combination - in combination with other means (soundproof and sound absorbing). The design must be at least 40-50 mm thick.

Pl groups

The Paladium brand is owned by the Moscow company PL Group, which produces dry building mixes. The soundproofing mixture Paladium is made with foam glass. It is universal, suitable for work on facades and indoors. The coating made from this mixture has been serving for more than 10 years. The warming fire-resistant material, easy in drawing, steady against biodefeat.

Favorite

De Luxe is a brand of the Russian company Favorit. Heat and sound insulation mixture Teplolux is notable for its low cost. It is steady against moisture therefore it can be applied in bathrooms and other damp rooms. Universal. It can serve as protection of facades and rooms for a long time. Withstands temperatures in the range of -50 ... + 50 ° C.

Combined Soundproofing Method

When the thickness of the plaster coating is doubled, noise reduction does not occur. Puff sound-absorbing coatings work most effectively, therefore it is better to place other sound-proof sheet coatings under the acoustic mixture - mineral wool (preferably basalt) or polystyrene. Such a coating will provide additional heat savings.

First, a soundproofing sheet material (foam, corrugated cardboard panels with a filler, etc.) is mounted (glued) onto the wall. After the glue dries, they start plastering. The main disadvantage of the combined method is to reduce the free space of the room (the coating is large thickness).

Correctly applied soundproofing plaster will help to make life more comfortable in the house. Even a layman can handle this. The main thing is to follow the recommendations and do everything in a quality manner.

Material Features

The decoration of most apartments is dominated by gypsum plaster. It aligns the surface well and serves as a decorative coating, but has low sound insulation. Therefore, in rooms with thin overlap, it is recommended to perform additional installation of sound-absorbing materials with a porous and soft structure.

There are several popular options suitable for installing sound insulation:

- Mineral wool and fiberglass plates. They are characterized by high efficiency, but the thickness of such plates often exceeds 3 cm. In addition, they are mounted in specially prepared frames, sheathed with sheets of drywall. Therefore, choosing this type of noise absorber, you need to be prepared for the fact that the area of the room will decrease.

- Polyurethane panels. They are made from special acoustic foam rubber. Panel mounting is simple. They "sit" on the glue and fix, leaning against the surface of the ceiling or walls. In this case, the working base does not have to be aligned, since the thickness of the material often reaches 10 cm.

- Liquid insulation. This option is available in the form of a mixture, which must be applied in a thick layer directly to the plaster. Installation does not require special finishing, since after completion of work the walls or ceiling must be covered with decorative plates or drywall sheets.

- Roll and sheet cork. This coating is considered decorative, but thanks to its special structure and thickness, it can also be used to eliminate extraneous sounds. Typically, the plug diameter reaches 6 mm.

- Soft fiberboard panels. They are a structure consisting of layers of expanded polystyrene, special waterproofing and reinforcing mesh. The thickness of the layer of filling material may be different (from 1 cm to 10 cm).

- Blocks of fiber array. For their manufacture exclusively conifers are used. Soundproofing material is characterized by excellent quality and a thickness of up to 2.5 cm.

- High density membranes. They have a thin and uniform appearance, conveniently attach to the surface and perfectly absorb noise.

All of the above materials are unique in their own way and have excellent characteristics, so you can purchase any option for installing a sound insulation system.

How to choose

Having decided to protect their apartment from extraneous noise, many begin to wonder what exactly needs to be done to install reliable sound insulation. The choice of material, as a rule, depends on the area and shape of the room.

If the room is small, then isolating it from extraneous sounds using thick panels or blocks is undesirable.

To choose a building material that is ideal for this purpose, you need to consider not only the size of the room. It should be borne in mind that sound insulation depends on the density and thickness of the protective fencing.Therefore, the surface of the walls and ceiling, which previously passed the lining with plaster, must be covered with a material that can reflect sound. As a rule, these characteristics are possessed by panels and plates with a granular, cellular or fibrous structure.

Masters recommend giving preference to the installation of complex structures consisting of several layers of a sound absorber. In addition, it is desirable to acquire fibrous and porous material. An excellent result can also be obtained from a combination of drywall sheets with special panels.

Recently, many affordable materials have appeared on the market, the external data of which are completely identical to polystyrene foam and polystyrene. But, as practice shows, their ability to absorb sound is low, so they are not suitable for the above purpose.

When choosing a material for sound insulation, it is important to carefully study its characteristics, operational properties, environmental friendliness, fire safety. Only in this case your purchase will be successful.

Look at the types of sound insulation in the next video.

Soundproof Membranes

Soundproof membranes are not able to hold sound, since it is just a film of average thickness of 2-3 mm. In the matter of reducing the sound throughput, it is used together with cotton or cork panels. The combination used allows for absolute sound insulation.

- modern thin, lightweight material,

- ease of installation

- high tensile strength.

- the need for combined use,

- high price.

Soundproof panels

Insulating panels, also known as sandwiches, are widely used in apartments and houses. Their popularity is due to the availability and the possibility of design. The outer side of the panel may be decorative. The decoration is made of plastic, stone elements, bas-reliefs.

- high sound insulation properties,

- strength,

- durability.

- high price,

- the complexity of installation - the panels are mounted on the wall with dowels, the joints are filled with a special solution, for example, foam for sound insulation.

Other materials

In addition to the listed products for soundproofing the premises are used:

- thermoacoustic insulation,

- Isoplat,

- acoustic drywall

- liquid insulation.

Termozvukoizol - rolled three-layer insulating material. The outer layers are made of polypropylene, the inner is mineral wool. Among the advantages are fire resistance, environmental friendliness, ease of installation, low level of thermal conductivity. Disadvantages: large thickness, difficult installation.

Isoplat - porous slabs made from wood fibers. They have one smooth side, which allows it to be processed. Invoice Isoplat allows you to align the walls during installation. Of the advantages stands out environmental friendliness, durability, ease of installation, processing. Disadvantages - high price, lack of resistance to moisture.

Kraft cardboard is a thin, lightweight insulator. It is made of paper, felt and wood fibers. This composition allows you to achieve high soundproofing properties. It can be installed on walls with any suitable adhesive. Kraft does not require a framework.

Soundproof gypsum board is perforated gypsum boards with mineral wool glued on the back side. On some models, the holes are filled with foam. Such GCR allow you to simultaneously insulate the apartment and protect it from noise.

Liquid insulation is a polyurethane composition that is applied with special equipment to the walls with a layer of up to 3 cm. It can be placed outside the house or inside. This modern method receives extremely positive reviews, as it allows you to achieve good protection against noise, align walls and insulate the room.

Acoustic plaster is a good sound absorber and insulation. The basis of the composition is made of gypsum or cement. Properties are achieved due to the filler from pumice crumbs or slag. Soundproofing under the plaster allows you to get absolute protection from noise.

Calculation of the amount of materials

Before buying soundproofing, you need to calculate the amount of materials. This can be done by using the services of professional masters or by applying the budget option - a specialized calculator.

The network has many programs of similar functionality. Demand is Rockwool, TechnoNICOL.

Rockwool has two modes of operation: standard, design. To calculate the amount of resources needed, you need:

- determine the type of building envelope (floor, wall or ceiling),

- indicate their type and size (light or massive, single-layer or multi-layer),

- assign additional insulation layers, their sizes.

The result of the calculation is the noise isolation index of air and shock type after installation.

The TechnoNICOL calculator has more functionality. To calculate, you need to follow the algorithm:

- Choose the type of room.

- Indicate the type of design.

- Identify the main sound sources.

- Choose from the proposed standard structural solutions for insulation.

As a result, the sound absorption index after completion of work and the amount of necessary materials will be obtained.

Manufacturers rating

TOP companies that produce sound insulation for apartments and houses:

The rating is based on open voting by consumers. Information from June 2019.

You can isolate the apartment from extraneous sounds using various materials. The range allows you to choose an option for any budget. Before buying, it is important to prepare an installation project and calculate the required amount of resources.