Pipes for underfloor heating have long been proven to be effective in space heating. They are used as the main, reserve, alternative or auxiliary means, providing normal conditions for human life.

Given the location of the structure in a region with a mild climate, they may well play the role of the main source, in the middle lane and in the north they perform an auxiliary function. But when choosing them, you need to be extremely careful and acquire only high-quality and durable materials.

General requirements in materials

It should be noted that for a warm floor it is better to use special materials designed for these purposes. Only if this condition is met, the system will last a long time.

It is recommended to refrain from similar analogues, since they are not intended for use in such structures and can burst at any time. Therefore, before buying them, it is recommended that you familiarize yourself with the requirements for which pipe is best suited for a warm floor.

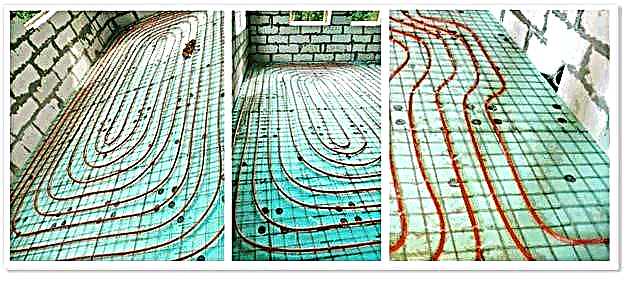

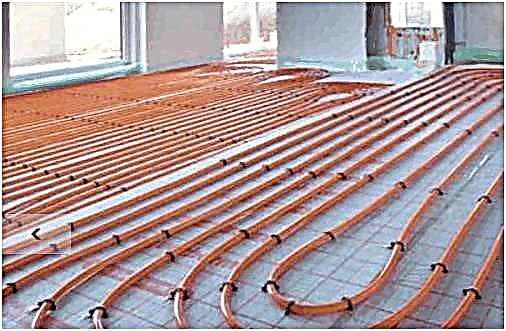

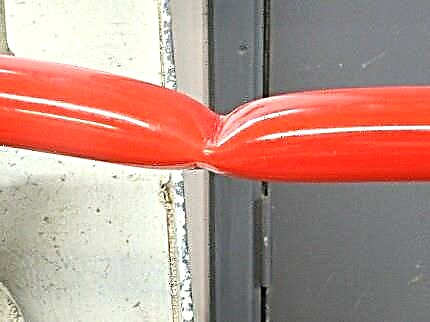

The system should be mounted only from a single piece of pipe, any connections are unacceptable. In addition, it is necessary that it be ductile, which will fill all areas of the room without increasing stress on its wall.

It should be noted that some photographs of a heated floor made of polypropylene-based pipes welded in places of bends are a direct violation of the technology.

In addition, there are a number of requirements for the choice of material. Based on these characteristics, you can independently choose which pipe it is desirable to use for the warm floor of your room. Here are the main ones:

- The product must have high mechanical strength. The pipeline in the mode of its operation is subjected to high physical stresses associated with the pressure of the system inside it and external from the concrete screed and furniture installed on the floor. Therefore, it must withstand a maximum load of at least 10 bar.

- It is recommended to choose a material only one that is not subject to thermal deformations under the influence of high temperatures.

- The inner walls of the pipes used to install the underfloor heating should be perfectly smooth without roughness. This will reduce the resistance to water circulation inside them. In addition, with uneven walls, fluid movement can be accompanied by murmur.

Basically, pipes for underfloor heating have a diameter of 16.20 or 25 mm. It should be noted that the number of fasteners for the pipeline will depend directly on this value and the average temperature of the liquid inside the system.

Official

In this case, you can build on the official documentation governing the characteristics and method of use of materials:

- SNiP 2.03.13 - 88, characterizing the provisions on the application and arrangement of the capital base, flooring and all communications located in the floor.

- GOST SP 41-109-2005, which combines all the rules of how polyethylene pipes should be used in heating and plumbing systems.

- GOST SP 41-102-98, similar conditions for metal-polymer products.

- SNiP 41-01-2003, characterizing issues related to pipes for a warm water floor, indicating data from checks for tightness of systems.

Despite the official codes of practice and standards, the work must be done carefully and carefully. Failure to comply with these requirements may lead to depressurization of the system and flooding of the apartment or house.

Independent choice

Which pipes are better for heating a room using underfloor heating technology: metal or polymer?

Each of the materials has its advantages and disadvantages, so the choice is determined based on the specific characteristics of the premises, the region in which the building is located and the financial sufficiency of the owner.

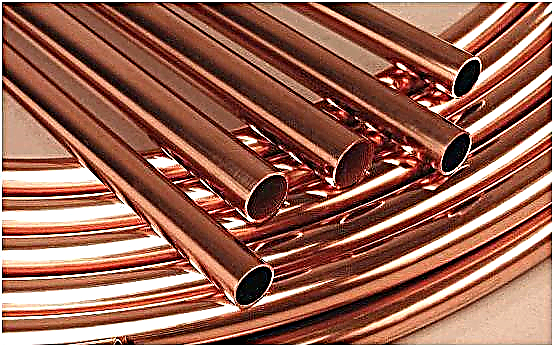

A review of the properties of the copper pipeline characterizes it as the best option for installing such systems.

The only thing that does not allow them to be massively used is the high cost of the material and complex installation technology, which again affects the cost.

But the advantages characteristic of copper pipes allow us to confirm the above statement about their advantage among analogues:

- The metal has high corrosion resistance, from this we can conclude that the system will last a long time.

- Pipes are plastic, so if all the conditions for technological installation were met, they can be bent in different angles.

- Copper has a good indicator of thermal conductivity, which ensures maximum heat transfer.

- The density of the material allows us to talk about its resistance to pressure and temperature differences of the liquid in the system.

Stainless steel

The disadvantage of special corrugated stainless steel pipes, as in the case of copper, is the high cost of the material. Despite the fact that a water heated floor made of such material appeared relatively recently, it has already established itself on the positive side.

Moreover, the metal eliminates the possibility of corrosion, from above it is covered with an additional polymer coating. The advantages of the material are similar to the previous one, the only difference is that the stainless steel does not have such good thermal conductivity as copper. But unlike it, it bends much more easily and confidently holds this bend.

Corrosion-proof pipes for underfloor heating can be used with the use of numerous fittings designed for connections and wiring of individual segments.

In this situation, this is the only material for which it is allowed to make mounting connections in the floor under the screed. Its quality gives a 100% guarantee against possible leaks.

Metal plastic

Metal-plastic pipes for underfloor heating are the most acceptable option for mounting the system at a price indicator. Compared to metal structures, polyethylene is several times cheaper, which suggests its wide popularity.

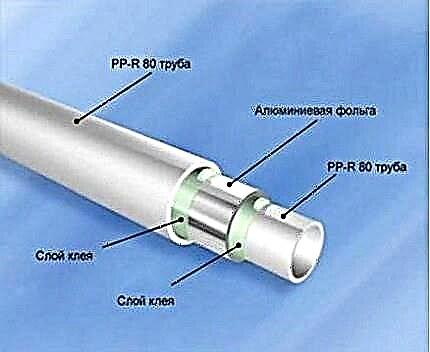

In addition, the material has good indicators of efficiency and durability. Good heat transmission capacities are primarily expressed due to the aluminum layer inside the pipe, which is protected on both sides by a polymer layer that protects from mechanical stress and salting. For more information on how to choose pipes for the floor, see this video:

Advantages are as follows:

- long life, not inferior to copper, up to 50 years,

- corrosion resistant

- environmental friendliness

- low weight of the whole structure is of considerable importance for some types of buildings,

- excellent soundproofing characteristics allow us to say that when the fluid moves inside the pipeline, this will not be heard.

Check the quality of the metal can be as follows. When heated to 90 - 100 ° C, the pipe should retain its appearance. If the layers of which it consists become visible, it is recommended to refrain from using such material and use another manufacturer.

How fundamental is the correct choice of pipes for underfloor heating

Water heating system, when the channels through which the coolant circulates are laid on the floor and warm water circulates through them, at first glance it is simple and understandable. Another thing is how to carry out the installation of the pipeline on the prepared surface, correctly lay the loops of the water circuit, ensure a reliable connection of the pipes and, accordingly, connect the finished pipelines to distribution equipment. This raises many questions to which you need to look for the right answers and, accordingly, make competent engineering decisions.

Different tasks can be assigned to the warm floor at home. Some people prefer to use this option for heating in limited areas of residential premises. Others pose large-scale tasks for warm floors - heating the entire living area of an object. The pipe for the warm floor in this case plays an almost decisive role. The quality of the pipe, its strength and reliability are the main conditions for the effective operation of the heating system, especially when it comes to the long length of the water circuits.

Currently, the market for consumables for heating systems is quite diverse. In the distribution network you can see consumables specially designed for floor mounting, differing in the method of manufacture and composition. At first glance, only the cost of materials can be decisive in terms of choice, but in fact, the issue of choosing a water main should be taken more carefully. "There are a number of criteria by which to choose a consumable for heating circuits of underfloor heating."

Among the most important criteria, the following aspects should be noted:

- the cross section of the water channel should not exceed 16 mm, given the thickness of the screed,

- all consumables must be labeled accordingly, designed for use in low-temperature heating systems,

- the ability of the pipe to withstand significant differences in the working pressure of the coolant in the system,

- technological resistance of the material to high temperatures,

- the resistance of the pipeline to mechanical stress and the reaction of the material to heat,

- ease of operation, including the implementation of routine and emergency repairs.

Important! When buying pipes, pay attention to the name of the company, the manufacturer. A well-known brand will guarantee you the quality of consumables, the reliability of the entire heating system.

In most cases, today, preference is given to working with metal-plastic and polymer pipes, which are based on cross-linked polyethylene. Such materials have already been tested in practice and serve as the main elements of the pipelines of heating systems for more than one year and in a variety of conditions.

If you wish, and with financial opportunities, you can bet on copper pipes, but in this case, the warm floor will become gold for you, in the literal sense of the word. Underfloor heating, in which the pipe is the main working element, can have different lengths. Doing floor heating throughout the house using expensive consumables is a thankless task. Copper pipes are suitable for mounting a water circuit in the bathroom or in the kitchen. Using copper pipes for other purposes is a waste of money.

Each type of main water circuits used in heating systems of underfloor heating has its own technological characteristics. Accordingly, pipelines in this situation have different technical parameters and differ in installation conditions.

For reference: in the practical plane, plastic products are most often used. Up to 90% of all water floor installations are made from polymer materials. The reason for this popularity and prevalence is that this consumable is affordable and convenient from a practical point of view.

What are the options when choosing the best consumable for underfloor heating? Let's take a closer look

Option one - use copper pipes

In this case, dwell on this option for a long time. It has already been written above that copper is an expensive pleasure for a warm floor. Here, not only the cost of consumables is taken into account, but also the complexity of installing the entire heating system. Piping of copper pipes is carried out using special equipment and in compliance with a certain technology, so you will not be able to do this heating option yourself. Despite the high cost of copper pipes, and the costs associated with installation, such products have high technological characteristics. Copper conducts heat well, and are highly resistant to corrosion.

Option two - plastic pipes

Unlike copper pipes, a good and convenient option for underfloor heating will be the use of metal-plastic heating water circuits. This material is quite common today and is quite popular.

For reference: metal-plastic pipelines have high efficiency and are durable. Having a layer of aluminum foil inside, metal-plastic pipes have a relatively high thermal conductivity. Thanks to the inner and outer layers of polymers, the products have the necessary strength and good resistance to corrosion processes.

The cost of such a consumable is considered acceptable, so many consumers rely on metal-plastic. The choice of which material, metal, copper, or polymeric materials made the pipe used for your underfloor heating, which is better, which is worse, is yours. All options have the right to implementation and do not differ in anything cardinal, except for the price. The following aspects are very important point to pay attention to:

- metal-plastic pipes are able to withstand hydrodynamic, thermodynamic and mechanical loads,

- the consumable is convenient in installation and in the process of further maintenance,

- products have significant life.

Today, manufacturing companies mainly produce a five-layer metal-plastic pipe, in which three layers are the main and two are adhesive, i.e. binders.

Due to the multi-layer metal-plastic pipes withstand mechanical and dynamic loads, which is important for the successful installation of the underfloor heating pipeline. Water circuits are laid in loops, in the form of a snake or a spiral, therefore, during installation, the water loop has many bends and turns.

The third option is polymer pipes made of cross-linked polyethylene

Copper or metal-plastic, which pipe is better for the equipment of underfloor heating, cannot be answered unequivocally. The answer to this question is the popularity of the third option, the use of polymer pipes. Products are made of cross-linked polyethylene. Amorphous and chemical neutrality of polymers provides water loops made from it with excellent resistance to high temperatures. The calculated temperature parameters at which polymer pipelines can be used make it possible to work with a coolant at a temperature of 95 0 С. All polymer consumables are specially marked PN.

On a note: For underfloor heating, a special PN 10 marking is used. In a pipeline with this marking, the working fluid pressure must not exceed 10 atmospheres. For PN10 brand products, the recommended maximum heat carrier temperature is 55 0 С.

The strength of the material is achieved through production technology. Crosslinked polyethylene pipes for underfloor heating should have a crosslink density of 65-80%. Depending on the surface treatment, crosslink density depends. The strength and tightness of the connections of all the loops into a single heating complex is ensured by special fittings. Using a welding machine, you can successfully make a water heating circuit of the required length. The length of the water circuit pipe for a warm floor is one of their main technological aspects of the implementation of the “warm floor” project. Unlike copper and metal-plastic pipes, polymer consumables allow you to build heating loops of the maximum allowable length (up to 120m).

The only drawback of this option of consumables for heating systems is heating floors, is a sufficiently large radius of bending of the pipe (8 diameters and more). In other words, with a channel diameter of 20 mm, the distance between the two lines of the loop will be at least 320 mm, which significantly affects the degree of heating of the concrete screed and flooring.

The fourth option, as an alternative - PEX pipes

The cheapest way to solve problems with installing a water circuit is to use PEX pipes. The cost of such a consumable is low. Such material perfectly transfers thermal energy to the floor covering and is designed for long-term operation. The only argument put forward by specialists in warm water floors when working with this material is the need for rigid fixation of the pipeline at the time of installation. If you neglect this remark, your pipe can easily bend and then the entire arrangement and layout of the pipeline will be violated.

To avoid such troubles, it is necessary to lay the heating circuit from these materials on a special substrate, in which cells for the main are provided.

How to calculate the optimal consumption of pipes for underfloor heating

If the situation with the materials from which the pipes for floor heating are made is quite understandable, then there are a lot of questions regarding the amount of consumables needed for the equipment of the heating system “warm water floor”. How to choose a pipe for installing a warm floor, and in what quantity, special calculations will help.

The material consumption is determined at the design stage of the heating system itself. It is necessary to proceed from the calculation that the maximum permissible length of the water circuit should not exceed 120 m. One loop of the water circuit should be made of one, single piece of pipe.

Important! The underfloor heating system does not allow the laying and installation of pipelines with multiple connections. The only exception may be fragments inserted into the body of the circuit during emergency leakage during the repair process.

On sale are pipes twisted into coils. As a rule, one bay is enough to cover the floor in a heated room with an area of 20 m 2. If the total area of the heated premises is known for you, then you can calculate the approximate footage of the water main. When calculating, consider the piping pitch, i.e. distance between adjacent loops. The maximum allowable step size is 35 cm. It is no longer possible, less, please, if you want to create a higher temperature in the room.

Conclusion

If you want to do everything competently and at the highest level, invite specialists for the installation of the heating circuit. You can independently perform work on laying warm floors in small areas. The correct calculation of the flow of water lines will provide you with significant cost savings.

Do not neglect the importance of design work for heating system equipment. The prepared project will ensure a normal installation, without excesses and failures. The result of competent work will be a complete heating system in your home, designed for long-term operation.

Features of the water floor

This heating method has been known since ancient times. The primitive water floor was used by the Romans to heat the Roman baths. Despite the fact that many years have passed since then, this heating method has not lost its relevance and is quite in demand among modern consumers. Today's water floor heating system has been significantly optimized - it is environmentally friendly, affordable cost, evenness of heating and the ability to configure modes using automatic thermostats.

This heating method has been known since ancient times. The primitive water floor was used by the Romans to heat the Roman baths. Despite the fact that many years have passed since then, this heating method has not lost its relevance and is quite in demand among modern consumers. Today's water floor heating system has been significantly optimized - it is environmentally friendly, affordable cost, evenness of heating and the ability to configure modes using automatic thermostats.

In general, water floor heating is a pipe system with various internal cross-sections through which the coolant circulates. Pipes can be made of various materials. Mats for warm water floors can also be used, the price of which is about 3-4 dollars per square meter. Mats and pipes are mounted on the floor, while a cement screed, a wooden or polystyrene dry installation system can be used.

In general, water floor heating is a pipe system with various internal cross-sections through which the coolant circulates. Pipes can be made of various materials. Mats for warm water floors can also be used, the price of which is about 3-4 dollars per square meter. Mats and pipes are mounted on the floor, while a cement screed, a wooden or polystyrene dry installation system can be used.

The main advantages that heated water floors provide include several factors:

more even heat distribution,

more even heat distribution,- use less energy to heat the air,

- creating optimal air humidity,

- lack of allergens and dust,

- prevention of mold and mildew.

In addition, the water floor in a private house or apartment is a cost-effective form of heating. In the long term, the costs spent by the owner to purchase equipment pay off and make it possible to use an inexpensive and energy-efficient system, the operation of which does not harm the environment and the ecology of the planet.

In addition, the water floor in a private house or apartment is a cost-effective form of heating. In the long term, the costs spent by the owner to purchase equipment pay off and make it possible to use an inexpensive and energy-efficient system, the operation of which does not harm the environment and the ecology of the planet.

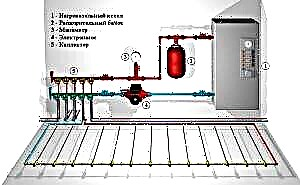

Before installation, specialists analyze the room and draw up a heating scheme that covers the entire house or individual rooms. The heating scheme developed by a heating specialist will give answers to many questions: which pipes are better for a warm water floor, how to position the boiler, and also help to determine the type of screed, the format of the fittings and auxiliary equipment used - thermostats, circulation pumps, hydraulic pumps, etc. .P.

Underfloor heating system - installation details

The main feature that should be considered by property owners who have decided to install a water floor is the high hydraulic resistance of this type of heating. Its indicator is several times higher than the similar values of the radiator heating system. In view of this, residents of apartment buildings do not always have the opportunity to use the underfloor heating system in the presence of district heating - this leads to cold risers in the entrance and inconvenience for residents of neighboring apartments.

These shortcomings are deprived of water heating of the floor in a private house - with the proper level of implementation, such a system will give the owner the opportunity to use a safe and environmentally friendly type of heating.

Organization Method

In order for the warm floor system to be efficient and safe, the temperature on the floor surface should be about 28 degrees. Only a condensing boiler can achieve such a coolant temperature on its own - laying heating pipes in the floor can be carried out directly from it. Other types of heaters - a conventional gas boiler, an electric boiler for a warm water floor - are designed for a minimum heating of the coolant at a level of 60 degrees. Therefore, too hot coolant must be diluted with a mixing unit.

The layout of the mixing unit is as follows:

- balancing valve

- circulation equipment

- mock valve

- thermostat system

- collector,

- control valve

- temperature sensor.

Using the mixing unit, the cold coolant from the return is mixed with the heated coolant coming from the supply pipe.

Criteria for choosing pipes for underfloor heating

Water heated floors are more difficult to install than electric, but much more economical. The main thing is to correctly design the system, select the best materials and correctly carry out installation.

The modern construction market is extensive, in the assortment there are many types of pipes that can be used for installation of heating systems.

When choosing, you need to consider such factors:

- strength and durability

- thermal conductivity,

- operational characteristics

- installation features,

- price-quality ratio,

- manufacturer reputation.

Materials for the manufacture of pipes are used the most diverse. Budget metal-plastic, polypropylene products and more expensive copper are popular. The outer diameter of the pipes is usually 16-18 mm.

Pipes should be selected for heating, and not for water supply. As for brands, you should trust trusted brands with a good reputation. It is important to buy original products, check with sellers for certificates so as not to purchase a fake.

Which pipes are better for underfloor heating? Strength test was conducted:

Option # 1: copper - versatile material

Despite the development of technology and the emergence of many new materials, copper is still a relevant material. Its main advantage is durability. Bacteria do not multiply on the surface of copper products. The material is resistant to corrosion, and pipes made of it can withstand high and low temperatures (from -100 to +250 degrees), mechanical stresses.

Copper pipes for a heat-insulated floor will not burst, will not melt, will not crack. Due to the high technical and operational characteristics, the material is applicable in modern heating systems. If all the conditions recommended by the manufacturer are met, the pipes can last up to half a century. This pays off the high upfront costs.

With all the advantages and excellent performance of copper pipes, they have limitations. The material is sensitive to hardness, acidity of water. If the coolant in the system creates an acidic or alkaline environment, the service life of the pipes can be halved.

It is not recommended to drain water from systems with such pipes too often. It is also undesirable to combine copper and steel, so as not to provoke negative electrochemical processes.

As for the installation, the connections of copper pipes using special press fittings are extremely durable. Their reliability sometimes exceeds the strength of the pipes themselves. Press machines are expensive equipment, so for installation you will have to invite specialists, which creates an additional burden on the budget when installing a heating system.

Option # 2: metal-plastic - reliable and inexpensive

A worthy alternative to copper is metal-plastic. This material is cheaper, therefore, is in great demand. Its advantages:

- durability (service life of metal-plastic pipes, as well as copper, up to 50 years),

- resistance to corrosion processes,

- environmental safety (polymers are environmentally friendly, they do not react with other materials and substances contained in water),

- light weight (this is a significant advantage compared to copper pipes, the weight of which is noticeably more),

- good sound insulation (moving through pipes, water will make less noise).

Plastic pipes consist of several layers, and the inner surface is perfectly smooth, which prevents the appearance of deposits on the walls of products. The polymer material that covers the pipes from the inside protects the entire structure from destruction and the negative effects of the coolant, the aluminum layer and adhesives.

The quality of the bonding layer is important. When the adhesive is destroyed, the layers of the metal-plastic pipe begin to move away from each other, which leads to leaks at the joints. To understand how high-quality composition is applied, you can heat the pipe to 90-100 degrees and look at the result.

If at the cut the product remains unchanged, then the “correct” materials and technologies were used in its manufacture. If layers become visible, it is better to choose pipes from another manufacturer.

Plastic does not tolerate exposure to open fire, but when installing a warm floor, this property of the material does not play a special role. But what really can become a problem is a poor-quality connection. If the pipe diameter is larger than the inner diameter of the fittings, then calcareous deposits can build up at the junction. This process is fraught with the appearance of leaks.

During installation, do not pinch the pipe too tightly with a union nut so as not to leave an incision that will later flow. It is better to invite professionals to lay a warm floor from metal-plastic pipes.

Crosslinked Polyethylene

A cross-linked polyethylene pipe for a warm floor consists of hydrocarbon molecules that are not interconnected. They combine under the influence of hydrogen and carbon atoms. This material is called PEX.

It has good performance for use in this technology. Strong enough, resistant to mechanical stress and high temperatures.

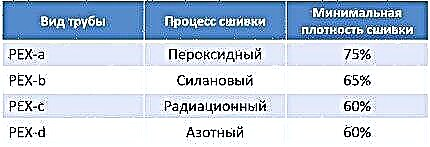

It should be noted that there are several types of cross-linked polyethylene pipes. Classification is carried out based on the processes of crosslinking of molecules, which affects operational performance and durability.

Materials with a low degree of crosslinking are susceptible to cracking, and may be damaged by mechanical action.

In total, 4 connection methods are known:

It is better to use pipes sewn in the first two ways for a warm floor, since they are the most durable in terms of performance.

Despite the fact that the material is somewhat more expensive than metal, it is much cheaper to mount it than metal systems.

The advantages that will be characteristic of the design if the installation of pipes for the underfloor heating made of cross-linked polyethylene is carried out are as follows:

- It functions perfectly in the range of operating temperatures from 0 to 96⁰.

- Used for laying using underfloor heating technology, it has a molecular memory. When heated, it can slightly deform; after cooling, it takes its previous shape.

- It has a good indicator of resistance to chemical components contained in water. It is not subject to corrosion and does not contribute to the formation of mold.

- It perfectly holds internal and external pressure up to 10 bar.

- It bends and recovers well.

- The choice of a polyethylene pipe for a heated floor, sewn according to this technology, allows you to perform the installation yourself. The procedure is quite simple.

To a greater extent, when confronted with the question of which pipe for underfloor heating to use for your house or apartment, the advantage is given to metal-plastic or polyethylene cross-linked elements. This is due to good performance, low cost and the ability to perform installation on their own or with the help of specialists, but with minimal installation costs (work on metal pipelines is much more expensive). On the intricacies of installing a polyethylene warm floor, see this useful video:

But, despite the amount that the installation process will cost, the costs will pay off due to the additional heating source of the room connected to the main one. In addition, living in such an apartment will become more comfortable, because stepping on a warm floor is much more pleasant than on a cold one.

How is the distribution of coolant along the contours?

To evenly distribute the coolant over several circuits involved in the system, a special device is used - a distribution comb or collector. It is a block of two interconnected supply and return pipes, to which all the circuits used in the house are connected. In small apartments or in the case of heating a separate room, only one loop of pipes can be connected to the collector. When heating large buildings, the number of circuits can increase significantly.

Using a collector has several functional advantages, among them:

- the ability to control the temperature in each circuit of the warm floor,

- the ability to automate work by integrating a comb with a thermostat,

- stepless pressure regulation in circuits, etc.

In general, the collector connection of a warm floor suggests the following nodes:

servo,

servo,- pump group equipment,

- switching center

- temperature regulators

- temperature control group.

For safety reasons, a gas or electric boiler for underfloor heating is equipped with a bypass. It allows you to ensure continuous operation of the system in the event of an emergency and makes it possible to avoid boiler failures due to overheating of the coolant or increase in pressure in the circuit to a critical level. With the help of a bypass, part of the coolant is removed from the main circuits and during emergency situations the boiler remains safe.

System stacking

In any system of underfloor heating, there are two key components - these are heating pipes in the floor, as well as a system for fixing them. There are several pipe fixation technologies available to modern homeowners.

A dry wooden or polystyrene fixing system is a plate made of wood or polystyrene mats, in which there are niches for placing pipes.

This type of fixation is quite effective - it allows you to evenly distribute heat, it is simple and affordable. After the pipes have been laid, a certain hard coating is laid on the fixing system. Then, tiles can be laid on a water heated floor, or other flooring options are installed, such as laminate, carpet, linoleum, etc. The use of cement-sand screed based on Portland cement is also quite often practiced when installing warm floor.

This type of fixation is quite effective - it allows you to evenly distribute heat, it is simple and affordable. After the pipes have been laid, a certain hard coating is laid on the fixing system. Then, tiles can be laid on a water heated floor, or other flooring options are installed, such as laminate, carpet, linoleum, etc. The use of cement-sand screed based on Portland cement is also quite often practiced when installing warm floor.

It implies several layers arranged alternately:

- insulation

- tape or mesh for fixing,

- pipes

- screed

- flooring.

The choice of a certain type of screed should be made individually. It should be understood that each type of screed has its own nuances, but because of the cheapness, a screed using cement is a more popular option. The high cost of a warm water floor using a dry screed format confuses some buyers who do not take into account the fact that a polystyrene or wooden fixation system is better for maintainability and lighter weight than a wet cement-based screed.

The choice of a certain type of screed should be made individually. It should be understood that each type of screed has its own nuances, but because of the cheapness, a screed using cement is a more popular option. The high cost of a warm water floor using a dry screed format confuses some buyers who do not take into account the fact that a polystyrene or wooden fixation system is better for maintainability and lighter weight than a wet cement-based screed.

In rooms where for some reason installation of a water floor is not possible, the heating problem can be solved using infrared heating elements. Among them, Heathlife heating can be bought, the price of which is $ 15-20 per square meter of film.

In rooms where for some reason installation of a water floor is not possible, the heating problem can be solved using infrared heating elements. Among them, Heathlife heating can be bought, the price of which is $ 15-20 per square meter of film.

Pipe selection

Pipes are one of the main elements of an underfloor heating water system, so it is worth choosing them responsibly. They must meet two requirements - bend well and be durable. Most often, the use of metal-plastic, polymer and corrugated stainless pipes is practiced. The best indicators of thermal conductivity are characterized by stainless steel pipes, but today their use is not particularly common because of their low popularity.

In addition to choosing pipes from the optimal material, the owner will have to choose a pipe with the correct configuration. The diameter of the inner cross section of the pipe may vary. It is determined after a series of hydraulic calculations.

Various modified laying patterns can also be applied, taking into account the individual layout of each room.

Boiler selection

An effective water floor heating kit which is selected in accordance with the heating scheme, cannot function normally without a correctly selected boiler. There are boilers that are specifically designed for the underfloor heating system. Among them are modern condensation models from various manufacturers. Traditional gas, solid fuel, electric and diesel heaters can also be adapted for use in the underfloor heating system.

The choice of a warm floor system has many nuances. The consumer should decide on the type of pipes, the type of screed, the choice of the boiler and flooring, so the implementation of the warm water floor system should not be carried out in a hurry. High-quality system components, selected in accordance with the specifics of the building, will allow for uniform, economical and productive heating.

The choice of a warm floor system has many nuances. The consumer should decide on the type of pipes, the type of screed, the choice of the boiler and flooring, so the implementation of the warm water floor system should not be carried out in a hurry. High-quality system components, selected in accordance with the specifics of the building, will allow for uniform, economical and productive heating.

Evaluation Criteria for Pipe Materials

To choose the right pipes for a warm floor, you need to have a good understanding of the operating conditions of the material. Being inside the screed, the heating line not only transfers heat to the monolith, but also experiences mechanical stresses from water pressure and its own expansion.

The pipeline body experiences pressure from two sides - from the pressure of hot water and the mass of the screed

Accordingly, strict requirements are put forward for the material:

- Underfloor heating (abbreviated as TP) is a low-temperature heating system where water is heated to a maximum of 55 degrees, the operating mode is approximately 40/30 ° С. To quickly transfer energy from the coolant to the concrete slab, the pipe walls must have sufficient thermal conductivity.

- The length of the TP loops often reaches 100-120 meters (depending on the chosen diameter of the pipeline). Longer length = high hydraulic resistance, exacerbated by the roughness of the inner surface. In simple language: the smoother the pipe walls, the easier it is for the pump to pump water along a long circuit and provide the required flow rate.

- Heating causes elongation of the underfloor heating pipes. Since there is nowhere to grow inside the concrete screed, one of two conditions must be met: a small coefficient of thermal expansion of the material or high elasticity and strength of the shell, allowing the pipe to fit in a limited space without breaking.

- Emergency: due to breakdown of the control valves on the mixing unit of the collector, the heating circuits are filled with boiler water heated to 70 ... 90 ° C. The material of monolithic pipes must withstand such temperature jumps without consequences.

- Other important points are corrosion resistance, protection against oxygen penetration, ease of installation and the absence of joints inside the monolith.

Note. For water circuits, laid "dry" method in wooden houses, less stringent requirements are put forward. TP are mounted without a coupler, there is plenty of room for thermal extension. Item 3 of the list is no longer relevant.

Not the least role is played by the cost of all TP components - pipelines, fittings, distribution comb. So let's compare the materials used by the above criteria and price.

Option # 3: polypropylene pipes

Polypropylene pipes for a warm floor are acquired by few, despite the obvious advantages - durability, environmental friendliness, low price. Demand for them is about the same as for copper. However, if copper products are scared off at their cost, then polypropylene is inconvenient for installing a contour of a warm floor.

The bending radius of the pipe is 8–9 diameters. If we compare with products made of cross-linked polyethylene, in which this indicator is 5, then polypropylene loses.

Large bending radius makes installation difficult. If the pipe diameter is 16 mm (allowable minimum), then it can be laid with a distance of approximately 128 mm. Most often, this is not enough to provide the necessary heat output. The disadvantages of the material include the installation temperature limit - not lower than 15 degrees Celsius, which is not always suitable for regions with severe climatic conditions.

Option # 4: cross-linked polyethylene pipes

Polyethylene is a material consisting of hydrocarbon molecules that are not interconnected. However, the use of new technology has allowed the molecules to be joined by the interaction of hydrogen and carbon atoms. The result is a new material called cross-linked or simply cross-linked polyethylene (PEX). It undergoes additional processing under high pressure, due to which new molecular bonds appear and strength increases.

Manufacturing technology was invented about 40 years ago, but cross-linked polyethylene has gained widespread use and popularity only in recent years. The material has unique properties that are not characteristic of its “predecessor”. It is durable, resistant to temperature changes, does not wear, does not crack and is not afraid of scratches. In many respects, the quality of pipes made of this material depends on the degree and method of crosslinking.

Below is a video demonstrating the resistance of cross-linked polyethylene pipes to various influences:

For a warm floor, you should choose a material whose degree of crosslinking is 65-80%. The operational properties and durability of the material depend on this. The higher the indicator, the higher the price of finished products, but these costs pay off. If the degree of crosslinking is small, then the material may crack, lose resistance to external influences. The method of combining molecules is also important. There are only four of them: peroxide, silane, radiation and nitrogen.

The advantages of the material include the following:

- Normal functionality over a wide temperature range - from 0 to 95 degrees Celsius.

- High melting and burning temperatures. Material begins to melt only when the temperature reaches 150 degrees. Burning temperature - 400 degrees Celsius.

- "Molecular memory." A cross-linked polyethylene pipe may be deformed, however, after increasing the temperature, it restores its original appearance and shape.

- Resistance to pressure drops. PEX pipes tolerate pressure changes in all types of heating systems. They withstand 4-10 atmospheres without problems (the exact figures depend on the type of pipe and are indicated in the technical documentation).

- Plastic. The material is extremely plastic, so it does not break, even if the product is bent several times in the same place.

- Chemical and biological resistance. PEX pipes are not sensitive to aggressive chemicals. They do not corrode, do not contribute to the growth of bacteria and fungi.

- Security. Crosslinked polyethylene does not emit any harmful substances into the atmosphere. Even when burned, it decomposes into water and carbon dioxide - substances that are safe for humans.

Although PEX pipes are recommended for use at 0-95 degrees, the material can withstand higher and lower temperatures. At -50 - +150 degrees, it retains strength and does not burst. However, operation under increased loads may affect its durability.

The installation technology of PEX pipes is quite simple and does not require expensive equipment. Everyone can master it. We offer a master class in installation:

PEX pipes are great for arranging a warm floor, and can be used for radiator heating systems and hot water. The material does not tolerate prolonged exposure to direct sunlight, but this is not important for a warm floor.

When transporting and installing, care must be taken with the anti-diffuse protective layer of pipes. If damaged, oxygen can enter the material structure, which will negatively affect the pipe durability.

Which pipes are still better?

Usually the choice is reduced to metal-plastic and PEX pipes. More and more people prefer the second option. However, the final decision, of course, is up to the buyer. To help, we offer a video, which describes in detail about materials for the manufacture of pipes:

If you are not confident in your abilities, it is better to entrust specialists with the design of a water-heated floor system, the selection of materials and installation. Additional costs for their work will pay off due to the long and trouble-free operation of the system. This is the case when excessive savings can affect home comfort.

Characteristics of polymer pipes

The following types of plastic pipelines are used for transporting coolant in water heating systems of apartments and private houses:

- PP-R and PP-RCT - polypropylene random copolymer reinforced with a layer of aluminum, basalt or fiberglass. Modification of plastic PP-RCT is characterized by increased thermal resistance.

- PE-X - crosslinked polyethylene grades A, B and C. The products must have an oxygen barrier - a thin layer of impermeable polymer. For example, Rehau pipes use the complex compound ethylene vinyl glycol (EVOH).

- PE-RT - thermally stabilized polyethylene products with an oxygen barrier.

- PE-X / Al / PEX and PE-X / Al / PE are five-layer metal-plastic pipelines.

Reference. According to GOST 32415-2013, for the installation of heating networks, products made of polybutylene RV, polyvinyl chloride PVC-C, polypropylene block copolymer and homopolymer (PP-B, PP-H) are also suitable. These materials are not widely used in private housing construction due to the worst technical parameters.

Briefly about how to connect pipe polymers in the process of assembling home heating:

- wiring from PP-R is joined by polypropylene fittings by soldering (thermal polyfusion welding),

- cross-linked and heat-stabilized polyethylene (PE-RT) is mounted axially in 3 stages - flaring the end, tensioning the fitting of the fitting, setting the sliding sleeve,

- metal-plastic is connected in 2 ways - compression or press.

Now we will give a brief description of each type of pipeline, go through the list of requirements and check how products are suitable for water heating of floors in living rooms.

Polypropylene - material for radiator heating

Despite the price attractiveness and commitment of many craftsmen to use PP-R, we immediately note that it is impossible to make a warm floor from polypropylene pipes. It is not worth checking the approval in practice - just carefully study the technical characteristics of the material and read the reviews of homeowners who wanted to save money in this way.

How are pipelines made of polypropylene (see diagram):

- the inner layer of PP-R, forming the passage section of the highway,

- aluminum reinforcing foil that inhibits thermal elongation and prevents the penetration of oxygen,

- 2 adhesive layers bonding aluminum to polymer,

- the outer protective layer PP-R is white or gray (some manufacturers have green).

An important addition. Now polypropylene manufacturers instead of perforated foil lay a layer of basalt or glass fiber inside the pipe.

Let's see how PP-R pipes are consistent with the requirements for floor heating branches:

- Thermal conductivity 0.24 W / (m • ° С) is the worst among polymer products. If we take into account the wall thickness of 3.4 mm at Ø20 mm (reinforced PP-R pipelines are not produced with a diameter of 16 mm), we obtain the heat transfer resistance R = 0.0034 / 0.24 = 0.014 m² • ° C / W. Resistance is too high for active heat transfer.

- There are no questions regarding the smoothness of the inner walls to polypropylene - a roughness of 0.01 mm does not create increased hydraulic resistance.

- When heated to 50 degrees, a 100-meter PP-R pipe with an aluminum layer will add 150 mm in length and 31 cm with fiberglass. The elasticity of polypropylene is very low, due to which the product inside the monolith will be under high load. Material may crack, primarily at joints.

Diagram of elongation of metal and polymer pipes as a result of heating by 50 degrees

Diagram of elongation of metal and polymer pipes as a result of heating by 50 degrees

Note. The technical parameters of PP-R products are adopted according to Valtec brand documentation published on the company's official website.We also took prices and characteristics of other pipe polymers from this manufacturer for fair comparison.

Explain some points. The value of the thermal resistance of the walls R = 0.014 m² • ° C / W will not tell the average user anything without comparison with the performance of other plastics. These calculations are given below in the descriptions of polyethylene and metal-plastic pipes.

The problem of heating polypropylene systems is the inability to visually check the quality of welding joints. Sometimes joints run a year after high pressure tests (crimping). Imagine the consequences of a leak inside a concrete monolith — searching for a defect, breaking the screed and repairing it.

If you solder the heating circuit from PP-R, a dozen joints will fall under the solution layer

If you solder the heating circuit from PP-R, a dozen joints will fall under the solution layer

A separate issue is a long fuss with installation, there will be many joints in concrete. Examples of heating circuits collected by house craftsmen from PP-R are shown above in the photo. Even the low price of the pipe Ø20 - 51 ... 83 rubles. (0.8 ... 1.25 cu) per linear meter - is not the basis for the use of such pipes in warm floors.

Parameters of crosslinked and heat-resistant polyethylene

Pipes made of plastic PE-X are produced in two varieties - 3 and 5-layer. The difference lies in the location of the anti-diffusion barrier - in the first case, the impermeable EVOH polymer serves as the outer shell of the pipe, in the second - it is laid inside the wall and glued to both sides of the polyethylene. External color - brown, silver, red.

Users often ask themselves which polyethylene pipes it is better to take for floor heating - PE-X or PE-RT, how do they differ. We answer:

- the molecular lattice of plastic PE-X is crosslinked in 3 ways, hence the three types of polyethylene - A, B and C,

- from the point of view of installation and operation of heating, pipes from PE-X / A do not differ from PE-X types B and C,

- material of increased heat resistance PE-RT is made from ordinary polyethylene using a cheaper technology - a complex polymer molecule is modified using branches,

- PE-RT is inferior to PE-X in terms of durability, strength and thermal stability,

- PEX is significantly more expensive than PE-RT, about 20-40%,

- PERT pipe walls lack an anti-diffusion barrier; therefore, the coolant is saturated with oxygen at a rate of at least 0.1 g / m³ • day. (on open air),

- PE-RT material is thermoplastic, the pipeline can be repeatedly melted and welded without loss of properties.

Reference. The cost of a Valtec 16 x 2 mm cross-linked polyethylene pipe is 51 rubles. per meter (about 0.8 cu). A product of the same diameter made of thermostable plastic PE-RT costs 33 rubles / 1 m. P. (0.5 cu).

Let's move on to our list of requirements:

- Pipe for warm water floor “PEX” and “PERT” has the same thermal conductivity - 0.38 W / (m • ° С). We calculate the thermal resistance of the walls with a thickness of 2 mm: R = 0.002 / 0.38 ≈ 0.005 m² • ° C / W - almost 3 times lower than that of the SPR. That is, polyethylene circuits much better transfer heat to the screed.

- An equivalent surface roughness of 0.007 mm is an excellent indicator of pipe smoothness.

- Having warmed up at 50 ° C, the 100-meter free section of the PEX pipeline will be extended by as much as 100 cm. But thanks to the elasticity and some mounting techniques, the expansion inside the concrete slab is quietly compensated by the material.

- The maximum working temperature of the PE-X material is 90 ° C, PE-RT is 80 degrees, the short-term allowable is 95 and 90 ° C, respectively. The operating pressure of the coolant is 6 ... 10 Bar, depending on the degree of heating. Parameters satisfy the requirements for heating water circuits.

The weak point of polyethylene systems is oxygen permeability. Equipped with a PEX barrier, it allows less than 0.1 g / m³ per day, while PERT allows much more. But since the pipes are monolithic with cement-sand mortar, air access is significantly limited, the penetration of oxygen is minimized.

Polyethylenes have a twofold property - molecular memory, which causes the pipeline to bend to the original shape of the bay. The feature complicates the fastening of heating loops to the floor insulation - if the pipe is not rotated around its own axis, the ends will begin to bulge upward. How to deal with the described phenomenon, look at the video of our expert.

more even heat distribution,

more even heat distribution, servo,

servo,