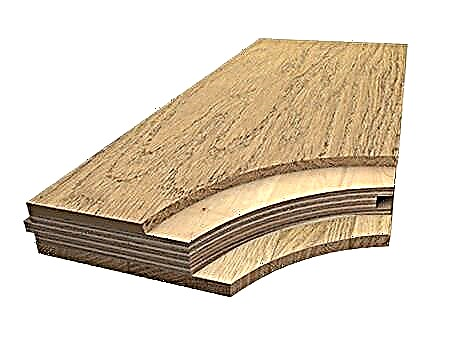

Covering the substrates with gypsum boards is a popular solution during repair work, but further manipulations with the surface require a special approach. For hanging interior items or equipment installation, it is necessary to use a specialized dowel for drywall, selected depending on the situation. If you make a mistake, the wall or ceiling can be seriously damaged.

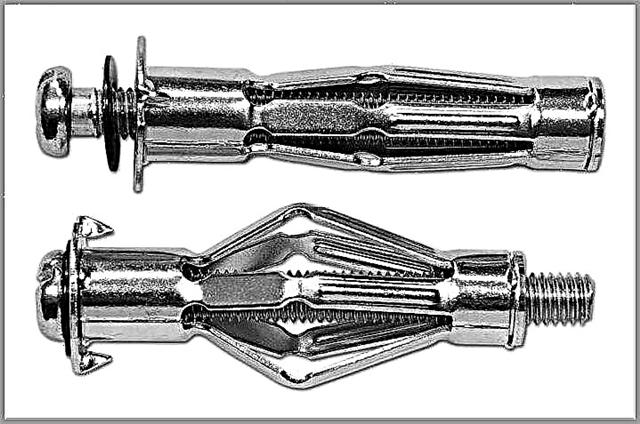

“Molly”

Pretty common option. The design includes two components, which is typical for most fasteners:

- The metal sleeve is a tube with sealed ends, inside of which there is a thread for a screw. The central part is divided into strips having a visible narrowing in the middle zone. Equidistant teeth are located on the neck.

- A screw is a metal fragment whose hat may have a different connector. It is supplied with an additional washer providing a large area of contact. The cost of fasteners exceeds the price of standard varieties.

Due to the use of a metal sleeve, the Molly dowel, in comparison with plastic analogues, can withstand a large load

Due to the use of a metal sleeve, the Molly dowel, in comparison with plastic analogues, can withstand a large loadFixation of the hanging object is carried out as follows:

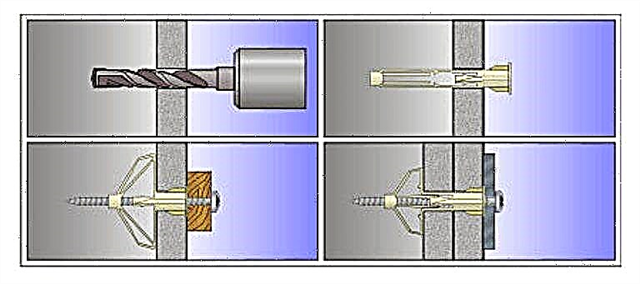

- A mounting hole is drilled, the diameter of which is most often 8 mm. But for accuracy, you need to measure the part or read the manufacturer's instructions.

- The sleeve is tightly inserted into the connector. If required, the part is carefully lined up until the teeth of the neck are fully engaged. It is important that the frame has the desired depth.

- A screw is screwed in, which is necessarily supplied with a washer. After the rod has completely passed the tube, efforts need to be increased, since the thread will begin to bend the sleeve in the center. Twisting should not be allowed: having reached an emphasis, it is necessary to stop, otherwise the plasterboard surface will break.

- Retention is carried out due to metal legs that open and abut against the wrong side of the wall. Most manufacturers claim a load bearing capacity of 50 kg, but it is recommended to consider not only the weight of the item to be hung, but also the configuration and purpose.

There are small spikes under the neck of the dowel that prevent the screw from turning, so they must go into the cardboard during screwing

There are small spikes under the neck of the dowel that prevent the screw from turning, so they must go into the cardboard during screwing The advantage of using molly is the possibility of dismantling: for this, the screw is unscrewed, and the recessed neck is gently pried. The part must be pulled out carefully, since the opened paws are not always in the initial position.

“Driva”

It differs significantly from the previous version, but is also popular. The fixture has the following device:

- Snail. It is a piece of hard plastic. A large spiral thread is located on the outer surface: the turns have a wide pitch and significantly protrude above the main part. A tip is located at the end, which most often has a jagged shape (see photo).

- Mounting screw. A special option is used, suitable for the internal connector.

For drywall, Driva plastic dowels are usually used.

For drywall, Driva plastic dowels are usually used.Technology of work with a variety:

- A hole with a diameter of 6 mm is drilled.

- The dowel is screwed into the connector. A hand tool or screwdriver with a suitable bat is used for the process. If work is carried out by an electric device, it is important to ensure that the speed is not too high.

- After installing the main part, the desired object is mounted, for this the screw is screwed in until it stops. The principle of operation is that the screw wedges the plastic case, creating the desired rigidity.

Although the “Driva” dowels are equipped with a sharp tip, for high-quality installation in the gypsum wall it is necessary to drill a hole, otherwise there is a high probability of turning during screwing

Although the “Driva” dowels are equipped with a sharp tip, for high-quality installation in the gypsum wall it is necessary to drill a hole, otherwise there is a high probability of turning during screwing It is taken into account that the variety has a small contact area, so the load on one fixture should not exceed 15–20 kg. Like molly, the product must be dismantled, but the site will require restoration.

Advice! There is a metal option used for hard surfaces, but for drywall it is better to choose a plastic one.

Dowel nail

This is a fairly popular standard type of product, which is more suitable for gypsum boards installed on the walls by glue. With a frame system, taking into account the sheathing in one sheet, the fasteners are not able to withstand a significant load, therefore it is used only for the installation of small parts. An exception is the surface of a double layer of drywall.

The structure of the dowel is standard: a screw and a plastic case, equipped with various elements on the outside that perform restraining functions. The size is selected individually, but the main rule is that the fastener is completely located in the sheet and should not protrude from the wrong side, because without support throughout the part will change position.

Fastening the product is quite simple:

- According to the diameter, a hole is drilled. It should ensure the entry of the entire plastic part.

- The body is driven into the seat.

- Although the screw can be screwed in, when working with drywall, it is better to adhere to the previous scheme, but with more caution. The fact is that when screwing the base can begin to slide in a circle.

Dismantling the product is not difficult, problems can arise only with the plastic part. With excessively strong fixation, the protruding neck is cut and the area is putty.

For drywall, special dowel-nail models are used, this is because standard plastic sleeves are too long and are not able to hold the screw on the sheet surface

For drywall, special dowel-nail models are used, this is because standard plastic sleeves are too long and are not able to hold the screw on the sheet surface

"Umbrella"

This element has a second name - "spring dowel".

- The main detail is a compressible mechanism having two locking blades.

- Threaded rod. There are standard options with a hat or with a hook. The presence of a lock nut and washer is mandatory.

The products are reliable, therefore they are used for hanging chandeliers and other objects on ceiling structures.

- A hole is drilled. The diameter is selected by a spring mechanism.

- Spaced apart blades compress so that they are in contact. It is considered that the screw must be screwed on securely.

- The compressed element is pushed into the hole to a characteristic sound, indicating disclosure.

- The rod must be tightened to the required level, after which it is fixed with a lock nut.

It is completely impossible to dismantle such a product, the mechanism will remain on the wrong side.

It is believed that the "Umbrella" is designed for hanging ceiling lighting fixtures, in fact, the mount is universal and suitable for both ceiling and wall structures

It is believed that the "Umbrella" is designed for hanging ceiling lighting fixtures, in fact, the mount is universal and suitable for both ceiling and wall structures

"Butterfly"

An excellent alternative to a dowel-nail. An ideal solution if you want to fix a small object: the load on one point should not exceed 8-10 kg.

- Plastic sleeve. According to the principle of action, it is similar to molly, but has only two legs, which, when fixed, fold into a shape resembling a butterfly (see photo).

- Steel screw with a threaded rod.

The installation technique and the device of plastic butterflies resembles metal mollies, but the bearing capacity of these fasteners is lower

The installation technique and the device of plastic butterflies resembles metal mollies, but the bearing capacity of these fasteners is lowerInstall the product as follows:

- A suitable diameter hole is created.

- The sleeve is compressed and pushed into the seat. The hull should be completely submerged. It is taken into account that this option is not suitable for two-layer methods of mounting plates.

- Screw is screwed in. Due to the attraction of the plastic part, the wings gradually fold and abut against the wrong side of the sheet.

Removing the element is quite problematic, so it is better to cut off the outer part and repair the defect.

Self tapping screw

This option is an improved version of the dowel nail. For work, two main varieties are used: nylon and metal. The product consists of a body and a screwdriver. The sleeve has a more modern structure, which provides better fixation in a drywall.

For this variation, the rules and styling technology typical of the dowel-nail are valid.

There is no clear distinction between self-tapping screws and dowel nails for gypsum plasterboard, therefore in construction stores they are often sold under the same name

There is no clear distinction between self-tapping screws and dowel nails for gypsum plasterboard, therefore in construction stores they are often sold under the same name

Other species

Less popular fasteners include several products. A small demand due to low prevalence and significant cost.

- Fischer. Fisher is distinguished by the structure of the plastic sleeve, which has a barrel-shaped shape, and a massive screw shaft with a fairly large thread. The principle of operation is that the housing expands from screwing. If the surface is thin, then the small paws straighten and abut against the material. Withstands from 10 to 15 kg.

The Fischer brand produces several models of fasteners, but all of them have more affordable domestic counterparts, so Hartmouth is not very popular. It is used when it is required to fix an object that creates a large load (up to 55 kg). The fastener consists of two elements: a plastic bifurcated part with a sleeve and a metal plate rotating on the fastener at the end and a screw.

The Fischer brand produces several models of fasteners, but all of them have more affordable domestic counterparts, so Hartmouth is not very popular. It is used when it is required to fix an object that creates a large load (up to 55 kg). The fastener consists of two elements: a plastic bifurcated part with a sleeve and a metal plate rotating on the fastener at the end and a screw.

Hartmut fasteners are really designed for relatively large loads, but with direct installation on gypsum board without a mortgage, you can attach no more than 15 kg to it, otherwise the drywall sheet will crack

Hartmut fasteners are really designed for relatively large loads, but with direct installation on gypsum board without a mortgage, you can attach no more than 15 kg to it, otherwise the drywall sheet will crack

Install products must be in a special way. Installation begins with drilling a hole, then the steel strip is aligned with the main part and pokes through, after which it is necessary to pull the plastic segments. This will allow the sleeve to move into the hole. More breaks off, screw is screwed.

Attention! It is considered that under the Fischer brand, fasteners are also produced, which is an alternative to Hartmouth. The difference lies in the presence of a metal guide along which the sleeve is displaced, and a durable polymer fastener instead of a plate.

Features of installation in drywall

To obtain a qualitative result, it is advisable to be guided by the following recommendations:

- The diameter of the hole should not be larger than the sleeve, the product should fit tightly.

- Given the declared load, it is necessary to take into account the structure of drywall. Any point impact can lead to deformation, so it is better to increase the number of mounting points.

- Screws need to be screwed in without pressure, when using an electric tool - at low speeds. If you turn the plastic case, then the work will be noticeably more complicated.

- The larger the fit area the product has, the better.

The use of dowels is recommended for hanging insignificant in weight and volume interior items, for heavy parts and equipment mortgages should be provided.

Tips

The choice of fasteners for drywall should take into account the constant load that it can withstand. In addition, we must not forget that some types of fasteners cannot be unscrewed without destroying the existing structure, therefore, it is necessary to clearly and accurately markup.

It is worth noting that the dowel butterflies are made in different sizes, but the most popular are 9x13 mm and 10x50 mm. It should be remembered that for the full opening of the dowel butterfly, you need to take a self-tapping screw with a length of not more than 55 mm. In addition, the masters advise taking into account the distance between the drywall and the wall.

The thickness of the item to be fixed using the butterfly is limited. As a rule, it is possible for them to attach a fastener to the wall with a thickness of not more than 5 mm, on which the interior item will be held.

Sometimes it happens that the length of the dowel-butterfly and self-tapping screw are longer than the space behind the gypsum board. In this case, a recess is drilled in the wall with a drill, which allows you to completely install the fasteners.

When drilling on the ceiling, it is recommended to use a disposable glass, which is put on the drill. This little trick will allow you to avoid cleaning the room from debris that will fall during operation.

Experts advise the material from which the dowels are made to be checked for elasticity. Fasteners made of too rigid plastic are more prone to kinks than others, so it can break immediately when fastened.

About the features of choosing a dowel-butterfly for drywall, see the next video.

Other varieties

To fix the chandelier, it is best to use spring-mounted fasteners. In addition to the spring mechanism, the dowel umbrella for drywall uses folding wings and a special metal rod, which puts these wings into action. Such a dowel is inserted into the hole with tightened petals, which the spring will unfold as soon as the fasteners reach the empty body.

The dowel "umbrella" has folding wings that open after screwing

The dowel "umbrella" has folding wings that open after screwing

Chemical anchors are a special capsule in which the adhesive mixture is located. The capsule will be crushed, and glue will flow out at a certain moment of fastening of such an anchor. A special chemical reaction inside the hole creates a connection that provides a secure fit.

Areas of use

Depending on the basis, it is necessary to correctly determine the approach and work process, taking into account its individual characteristics. Drywall sheets are brittle and easily damaged in comparison with wood, concrete, stone and other common materials. Do not use nails or screws without prior preparation. Professionals fasten sheets with dowels and screws.

The Driva key is actively used to work not only with gypsum board, but also with chipboards. The element is inserted using a screwdriver or screwdriver without special preparation. The installation process is not particularly difficult. Special tools and a high skill of professionalism are not required.

Dowels from the aforementioned manufacturer are used by both specialists from the repair industry and ordinary customers who prefer quality. If necessary, the element can be easily dismantled without damaging the base.

Double drywall dowel

For drywall use special fasteners. They have a drill tip, which allows you to freely screw it into a double sheet.

In addition to the above, there is also a self-installing dowel, trims and other types.

Fasteners Dreeva and Molly

Fasteners Dreeva and Molly

Fasteners Dreeva and Molly

Depending on which dowel under the drywall has the shape of a head and thread, it is customary to distinguish the types:

- Driva - is available in two varieties: metal and plastic, while the latter is considered more popular. Drywalls withstand plastic drills withstand excellent, and at the same time mounting them is simple. It is enough to drill a hole with a diameter of 6 mm and insert the product into it. After the cross nozzle, it must be cut into the sheet and screwed into the internal slot. Also, the plug for the drywall for drywall provides for the dismantling of the mount.

- Molly is a quality and therefore expensive fastener. They are characterized by high load thresholds and the possibility of dismantling. Molly dowel for drywall is characterized by a simple principle of operation.First you need to make an eight-millimeter hole with a drill. Then insert the product into the sheet and press down on the two-pronged side. In conclusion, you need to press the design to the sheet with a screwdriver on the internal thread.

There are two types of drive: metal and plastic, this type of fasteners is very easy to install.

As you can see, there is a wide variety of fasteners. Therefore, choosing them, remember that a certain screwdriver on drywall can be suitable for some purposes, and in other cases its use is unacceptable.

When the walls in the room are sheathed with sheets of drywall, the question arises of how to mount the mount for this small material, light things: paintings, photographs, small shelves and lamps, various souvenirs, jewelry and decorative elements.

After all, I don’t want to hang up a trifle, hammer a huge metal nail or use a powerful dowel, create massive fasteners by drilling the wall itself, which can be several centimeters from the drywall sheet, if the frame method of its installation is used. For these options, the butterfly dowel was invented, which is an excellent plastic fastener-anchor for hanging small and light objects on a drywall panel without screwing it into the main wall.

Characteristics of the dowel - butterfly

Characteristics of the dowel - butterfly

What are butterfly dowels for?

This device is intended for durable fastening of home interior elements to drywall. The expansion bolt shield for gypsum cardboard Butterfly consists of two parts: expansion and static. The spacer part is inserted into the hole made in the drywall sheet, and when screwing the threaded fasteners expands, thereby making the connection strong. There is a border on the dowel, which does not allow it to fall into the drywall. Many experts advise using the Butterfly dowel for attaching elements to drywall.

This is interesting: Mosaic panels - varieties of materials and styling methods

The principle of the butterfly anchor

The dowel-butterfly is a kind of self-tapping fastening device, which, thanks to its specific form, is tightened when tightened, tightly fitting with special paws to the back wall of the drywall sheet, which increases the area of the material under which pressure is applied from the weight of the suspended object. In other words, a dowel of this shape distributes the load exerted on the drywall.

This anchor fixture has a number of design characteristics:

- it is intended for fastening on a single (10-12 mm) or double (20-24 mm) layer of wall drywall (fastening can also be used on chipboard, gypsum fiber board and other sheet materials of the corresponding thickness),

- sold with self-tapping screws, suitable for its length and type of thread, but can be used with other screws, if they are suitable in size,

- on the part of the dowel, which is located inside the sheet of drywall, ribbed elements are applied that prevent the anchor fastener from rotating around its axis,

- the internal thread on the far head of the dowel contributes to its folding and clamping, and the special internal paws attached to this head contribute to greater rigidity of the structure in a twisted state.

The principle of the device dowel for drywall

The principle of the device dowel for drywall

Here is such a simple design that will allow you to suspend an object directly to the drywall sheet without using a long nail or dowel, which would have to be fixed directly to the main wall. In this case, an extra shoulder would be created, due to the fact that the nail or self-tapping screw in the dowel would lag behind the wall by the distance created by the inner frame, on which the drywall is attached.

Dowels for mounting products on a drywall wall

For fixing objects on drywall walls, a special dowel is designed, the end of which is equipped with cutting edges that perform the function of a drill. To install such a dowel in a drywall wall in it, it is not necessary to drill a hole in advance, which allows you to fix an object on the wall in the absence of a drill and drill.

After installation, a self-tapping screw is screwed into the dowel without changing the dowel geometry. The dowel can be easily unscrewed from drywall and reused.

There is another special dowel for mounting products on the wall of drywall called Molly (Molly). Its builders call it “Butterfly” because when screwing in the self-tapping screw, the expansion part of the dowel diverges to the sides behind the inside of the drywall, taking the form of butterfly wings. This is due to the fact that at the end of the spacer part there is a thickening in which a self-tapping screw is screwed, folding the spacer part of the dowel in half, firmly fixing the dowel in a drywall plate.

This dowel allows you to fix on a drywall product weighing up to 10 kg. Here with a dowel type Butterfly large mirror on the wall of drywall.

Specifications

The Driva brand produces two varieties of fasteners, namely:

For the manufacture of plastic plug-in spikes, nylon, polyethylene and polypropylene are used. The combination of these elements creates a durable material. The manufacture of metal products involves the use of a special alloy of low carbon steel, zinc and aluminum. Each of the above elements boasts strength, practicality and durability.

For products of the Driva brand, a constant and intense load is fearless. The metal dowel can carry 32 kilograms without any problems.

How to choose a metal expansion plug and other types of fasteners

Guided by special tables, it is easy to choose a latch to perform specific tasks.

The following points should be noted:

base material. After performing test drilling, by the color of the dust and the resistance of the tool, you can determine the type of building material,

current load

It is important to evaluate the magnitude and direction of the existing efforts, choosing the fixture of the required section and length.

Dowel latch is a convenient and reliable way to fix

It is important to be able to choose the right design and dimensions of the dowel, taking into account the tasks. This will ensure a secure fit for a long time.

Driv type plug

Perhaps the most popular drywall fasteners. It happens with and without a drill, metal or plastic. When making a hole for its fastening, a drill with a diameter of 8 mm is used. The manufacturer declares the working load on the slice, which GKL is able to withstand using this dowel, at 25 kg, while the maximum load is up to 50 kg.

The popularity of the Driva expansion bolt shield is caused by rather high reliability and rather low price. The strength of this fastening is achieved by distributing the load over a large area, which is provided by the shape of the dowel.

The drywall dowel is simple and effective.

The drywall dowel is simple and effective.

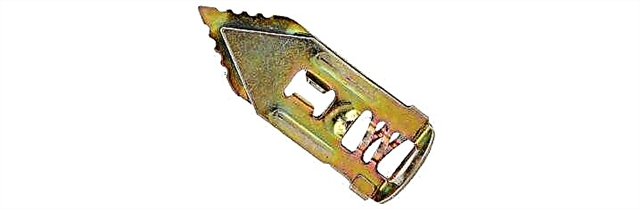

Flat dowel-nail

This dowel is made of refractory steel, is quite simple and easy to use, since it does not require additional drilling and, accordingly, will eliminate dust. It can be hammered into drywall with a hammer or pressed by hand, if possible.

The principle of the dowel-nail is that when the self-tapping screw is screwed into it, the initially flat front part opens, forming a reliable stop.

Use it for sheets up to and including 12.5 mm thick. Self-tapping screws choose a diameter of 3.5-5mm. The workload for tearing, declared by the manufacturer, is 15 kg, for a slice - 30 kg, the ultimate load on a slice obtained experimentally is 48 kg. Among other things, the nail dowel must be reused, that is, it can be dismantled and mounted in another place several times.

The flat dowel-nail for drywall is very easy to install, since it does not require drilling

The flat dowel-nail for drywall is very easy to install, since it does not require drilling

Universal expansion expansion bolt shield Butterfly

The butterfly dowel is suitable for both drywall and concrete foundation. The hole for its installation is drilled with a drill with a diameter of 8 mm, the diameter of the complete self-tapping screw is 4.5 mm.

For the butterfly dowel, we recommend using self-tapping screws without missing a thread, since when screwing in, having reached a smooth neck, the self-tapping screw will begin to scroll, and the dowel will not take the desired shape in the form of a stop.

In general, a plastic butterfly dowel works approximately like the rest, creating an emphasis on the GCR when screwing a self-tapping screw. The shape of such an emphasis is somewhat reminiscent of a butterfly, hence the name of the fastener. The rated working load on the dowel is 25 kg, the maximum load is 55 kg.

Drywall dowel for gypsum board is the most popular because it is equally inexpensive, convenient and efficient

Drywall dowel for gypsum board is the most popular because it is equally inexpensive, convenient and efficient

Dowel molly

The Molly dowel, or rather the Molly anchor (after all, this is an independent mounting unit that does not require additional self-tapping screws) is another popular type of fastening for drywall made of metal. This dowel, unlike the previous ones, is available in various sizes and, accordingly, under various loads.

For example, for Molly the smallest size marked 4/16/38 (4 is the screw diameter, 16 is the neck length and the maximum sheet thickness for which it can be used, 38 is the total length of the element), the working load is 25 kg, the ultimate load is 47kg

To make holes for Molly, a drill is chosen 2 times the diameter of the neck (the first number in the marking), that is, for the four it will be 8 mm, for the six - 12, etc.

To install the Molly dowel, you need a special tool that brings the fastener to “combat readiness”. With its help, the screw is slightly extended on itself, while the hooks are bent. Then you can turn the screw with a screwdriver, bending the hooks to the stop. All this should be done by inserting the dowel into the hole in the drywall.

If there is no special tool, it is possible to actuate the anchor using nippers (side cutters) or even an ordinary flat screwdriver.

Drywall Molly for drywall - a solution for professionals

Drywall Molly for drywall - a solution for professionals

Fischer twisting plastic dowel

When screwing a self-tapping screw into such a dowel, the latter is twisted, forming an emphasis behind a sheet of drywall, hence the name of the fastener. The drilling diameter for such a dowel is 8 mm, the diameter of the self-tapping screw is 5 mm.

When twisting the self-tapping screw, the main task is not to squeeze too much, otherwise it will begin to turn, and the fasteners will need to be re-performed. For this reason, using a screwdriver to tighten, set the minimum speed on it.

The working load on the separation of the twisting dowel is 10 kg, on the cut - 25 kg, crash load - 70 kg.

Curling plastic wall plug for drywall - an interesting and effective solution, backed by Fischer reliability

Curling plastic wall plug for drywall - an interesting and effective solution, backed by Fischer reliability

Varieties of dowels, “butterflies”

Such self-tapping fasteners tightly clamp when tightened, respectively, the dowel is quite reliable. The meaning of the design is that the clamping legs fit as close as possible to the back surface of the gypsum board sheets, so suspended chandeliers and other lighting devices will not bear the load only on a limited ceiling area. The load will be uniform.

As for the thickness of the dowels, they can be either from 10 to 12 mm or from 20 to 24 mm, which corresponds to a single or double layer of drywall. The equipment differs in self-tapping screws of various lengths and threads, although other screws can also be used if necessary. The rotation of the anchor around its axis is practically excluded due to the presence of several ribbed elements located inside the structure.

Dowel Butterfly

Dowel Butterfly

“Butterflies” for drywall are made not only of metal, but also of plastic and nylon. Metal products are more practical to use and last longer, but this affects their cost. Large loads are not terrible for them, as well as corrosive processes, since products are processed at the manufacturing stage with special compounds. To break or twist such a “butterfly” is almost impossible.

A more modern variation of dowels are products made of nylon and plastic. They are immune to rusting processes, affordable in terms of cost, but cannot compete with steel products in terms of the threshold of permissible loads and mechanical stability. As for the cost, the plastic will have about 32 rubles, and the nylon dowel will cost 26 rubles.

We consider products with the same size - 10 × 50, but steel dowels have completely different parameters, for example, a butterfly with a 4 × 24 screw will have to pay about 75 rubles.

Dowel Butterfly photo

Dowel Butterfly photo

Dowel Molly

One of the most common dowels for fastening in drywall is molly. According to the principle of action, the molly refers to expandable dowels, that is, during installation it “clamps” the drywall sheet between the front and rear. Molly is not the cheapest option, but it is a good solution if increased demands are placed on the reliability of installation. The advantages of molly include the ability to withstand high loads - up to 35 kilograms. It is dismantled if necessary.

Drywall dowel - Molly

Drywall dowel - Molly

Mounting molly is not difficult. To begin with, a hole with a diameter of 8 mm is drilled in the place where they are going to fix the dowel. Insert molly into it, press down the side with two teeth so that they fit tightly into the drywall. This eliminates cranking during installation. Then they screw in a screw - an element of the dowel, until the back of the moll presses against the drywall sheet. This is evidence that the installation is complete. No self-tapping screws are needed.

Fischer PD and PDS

Rounded nylon dowel. Longitudinal ribs do not allow turning. During the twisting of the self-tapping screw, its tapered shank enters the plastic sleeve, causing the wing-stops to open. Withstands up to 15 kg.

Knauf-Hartmut (Knauf-clamp)

Sensation in the field of fasteners. Such a wall plug can withstand up to 55 kg in the wall and up to 6 kg in the ceiling. The set of such an expansion bolt shield consists of a metal U-shaped strip, locking bushings, and two guides made of plastic.

For installation, it is necessary to drill a hole of at least 13 mm, insert the bar and align the guides. Then insert the plastic sleeve through both guides until it stops, then part them in different directions and remove. Thus, in the drywall, the strap is securely fixed, into which the screw from the kit is subsequently screwed.

Walraven BIS GOLD

This driving dowel is suitable for small and medium loads for screws with a diameter of 3.5 - 5.0 mm and a minimum length of 30 mm. The name of the fastener speaks for itself: you only need a hammer to install it. During driving into the wall, the dowel is independently wedged and does not scroll.

There are other manufacturers of dowels for drywall, for example: TOX and KEW (Germany), HILTI (Liechtenstein), SORMAT (Finland).

To save on the cost of dowels, most often they are bought in bulk in China. Despite the quality, some branded dowels will vary greatly.

Be sure to find out the country of manufacture of the mount from the seller, because safety depends on this.

What it is

The dowel-nail “butterfly” consists of a self-tapping screw and a plastic part that resembles the wings of a butterfly. The peculiarity of this fastener is that when the wings are twisted, they spread and are pressed to the back of the drywall sheet. This allows you to distribute the load, which is a big plus when working with such brittle material as drywall.

Also, this nail dowel has special ribbed sections that do not allow it to scroll in the gypsum wall. On the inside of the head there is also a ribbing that prevents the fastener from folding.

It differs from other dowel nails in a weight that it can withstand. Permissible load - up to 20 kg.

The expansion bolt shield "butterfly" can be:

The most common type is a plastic dowel. It is cheap to manufacture and therefore widely available. The advantage of plastic and nylon fasteners is their wear resistance: they do not rust. But it’s better not to hang heavy objects on them.

Metal "butterflies" are less commonly found on sale and are more expensive than analogues, but they can withstand heavy loads. Some manufacturers cover them with special rust protection agents, which is also a plus.

Driva expansion bolt shield

This is a metal, plastic or nylon hollow rod having a screw thread. In the head there are slots for a Phillips screwdriver.

It is more convenient to use the Driva plug type equipped with a drill. Then the installation is greatly simplified:

- Using a screwdriver, the element is screwed into the wall.

- A screw is screwed into the cross-shaped slot of the dowel, which bursts it from the inside. This ensures a solid fixation of the element in drywall.

The length of the dowel made of plastic is 23 mm, but the size of the metal dies varies from 33 to 44 mm. Therefore, when choosing fasteners, the wall thickness is taken into account.

The main advantages of mounting "Driva":

- Low price of hardware.

- Free space behind the ceiling is optional.

- Simply dismantle if necessary.

- Plastic models are designed for loads up to 25 kg, metal - up to 35 kg.

How to install

For all varieties, the algorithm is the same. So, step by step instructions for installing a polyethylene expansion plug is as follows:

Mark with a marker the intended location for future attachment.

- Make a 1-2 cm deepening with an awl.

- Choose a drill bit so that the hole matches the “chopper” and the self-tapping screw.

- Drill a hole 1 cm longer than the dowel.

- Clean the recess from building dust.

- Insert the dowel and hammer in.

- Screw on a self-tapping screw or screw.

As soon as the first hit on the dowel is made, the spacer mechanism will work. In this way, a firm fit is ensured.

Butterfly dowel

This fastener got its name because it resembles a butterfly in a tightened state. When a screw is screwed into it, the dowel wings open and abut against the surface of the drywall from the reverse side. To prevent scrolling of the element, special cuffs are provided.

By design, the “butterfly” can be considered as a lightweight and cheaper version of the Molly dowel.

This type of fastener is designed for small fixtures, cornices or skirting boards, fixing wiring, switches. According to manufacturers, it is able to withstand a load of up to 28 kg.

The installation instructions for butterfly dowels are simple:

- In the right place, using a drill of the appropriate diameter, a hole is made under the dowel.

- The side "wings" are compressed by hand, after which the fastener is inserted into the hole. It should go in tight, so it is recommended to use a hammer for precipitation. At the same time, the notches on the dowel body must pierce the drywall from the front side. This will prevent the item from scrolling.

- Screwing the screw in, it is necessary to achieve a tight pressing of the wings to the surface of the sheet on the back of the drywall.

The nuances of mounting the "butterfly" are shown in the video.

Application

They are used directly for decorating the premises with drywall, as well as for the interior decoration of a repaired or new building. That is, they are used in construction and construction.

Using dowels, sheets of drywall are fixed during installation:

- false walls

- niches

- ceilings

- skirting boards

- recessed fixtures.

Also, when you need to fasten together 2 or more sheets to strengthen the structure.

The expansion bolt shield is required when arranging, when you need to hang various interior items on a wall from drywall:

- paintings, mirrors,

- shelves

- hangers

- Wall Clock,

- flower pot with flowers.

An ordinary screw or self-tapping screw will destroy drywall and will not be able to hold even a small weight. The Driva dowel is screwed into the material with the help of a large-diameter thread with very rare turns, in shape resembling a drill. Therefore, it does not jump out and captures a sufficiently large area to which the workload will be transferred. Due to the distribution of weight over a larger area, the pressure on the material is reduced, and the fastening is many times more reliable.

Dimensions and specifications

There are 2 types of Fasteners manufactured - plastic and metal. According to the calculated characteristics, plastic can withstand a load of up to 25 kg, of metal - up to 32 kg.

There are 2 types of Fasteners manufactured - plastic and metal. According to the calculated characteristics, plastic can withstand a load of up to 25 kg, of metal - up to 32 kg.

Plastic dowels can be made of different materials:

All these materials equally meet the requirements for this type of fastener:

- strong enough for their own purposes,

- not destroyed, not deformed with time,

- do not lose their properties at temperatures from -40 to + 50С о,

- hygienic, not subject to corrosion and oxidation,

- do not form condensate, therefore smudges that spoil the interior are excluded.

Metal products are treated with an anticorrosive composition and also do not create problems throughout their service life.

The dowel has a sharp end, which facilitates its introduction into the material during the twisting process. The hat has slots for a Phillips screwdriver or screwdriver bit.

Plastic and metal fasteners are available in two sizes:

- from plastic - 12 by 32 mm and 15 by 23 mm,

- from metal - 15 by 38 mm and 14 by 28 mm.

Features of plastic and metal elements

The plastic fasteners of Driva are used as a base, into which an ordinary self-tapping screw is then easily screwed. They are used for the installation of light elements only on drywall. To fix 2 GKL sheets together, you can not use a self-tapping screw.

In some cases, a metal dowel can also serve as a separate fastener element. Metal in its properties is stronger than plastic, therefore metal is used for fastening heavier interior items, for example, cabinets. In addition to drywall, more durable - metal can be used when working with chipboard.

Benefits of using

Such fasteners are convenient and easy to use. During installation, special training or qualifications are not required. The only difficulty, as with any other method of fastening, is to precisely mark the landing places so as not to get away from them while screwing the dowels.

Such fasteners are convenient and easy to use. During installation, special training or qualifications are not required. The only difficulty, as with any other method of fastening, is to precisely mark the landing places so as not to get away from them while screwing the dowels.

Since they are used to work with soft material, it is very easy to twist them. No hammer drill, carbide-tipped drills are required, so there is no dust and noise.

Disadvantages

The disadvantages include load limits. But this is due to the properties of drywall for which they are created. The dowel itself can withstand much more than drywall can withstand. In this regard, Driva has a multiple margin of safety.

Sometimes the disadvantage is the excessive length of the product. If behind a soft drywall a structure made of solid material (concrete, brick, metal), the dowel cannot be screwed to the end. Then 2 options are possible:

- use fasteners for hard materials,

- screw in the dowel as far as possible, unscrew, cut along the length with a metal file exactly in size and return it to its place.

Mounting Procedure

Plastic and metal dowels are screwed into plasterboard sheets (GKL) without prior drilling. But this is if you need to attach the gypsum board to the metal profile, under plastic ones - pre-drill holes with a drill for metal with a diameter of 6-8 mm.

Plastic and metal dowels are screwed into plasterboard sheets (GKL) without prior drilling. But this is if you need to attach the gypsum board to the metal profile, under plastic ones - pre-drill holes with a drill for metal with a diameter of 6-8 mm.

Metal Driva has a rather strong tip - a drill, therefore it is screwed in without preliminary drilling.

If the profile is non-standard, with a thick wall and in practice, the metal dowel cannot be screwed into it, holes are also pre-made.

Work begins with the marking of the attachment points, then follow this scheme:

- The dowel is screwed in with a screwdriver, an electric drill with speed control or manually with a Phillips screwdriver. The size of the crosses on the bits and the screwdriver should correspond to the slots on the mount.

- The screwdriver or power drill should be adjusted to low speed.

- With the help of screws screwed into the dowels, the desired item is fastened tightly.

It is necessary to really assess the carrying capacity of drywall under vertical loads. The design strength of the plastic dowel is 25 kg at a break along the horizontal axis. But this does not mean that you can hang a 150 kilogram shelf with books on 6 mounts. Drywalls themselves may not be able to withstand such a load.

If on the subject of the interior there are secret fasteners, and a suspension is provided, and not a blind fastening, the self-tapping screw does not tighten to the end. The head of the screw, as well as part of its desired length, remains on the surface. They hang the item through the holes in the mounting brackets.

If necessary, it is also easy to dismantle, since together with self-tapping screws they are easily twisted.

The expansion bolt shield of Driva convenient in work and functional modern fixture. And when working with drywall, it is sometimes indispensable as the only type of fastening.